13

I N N O V AT I O N S • V O L . V I I , N O. 2 • 2 0 1 5

is the easy part; gathering the volumes of requisite

pipeline data, well … that could take decades.

Digging Up Details

In order for predictive software to deliver on

its promise, it requires a lot of data: pipeline

diameters, age, pressure, temperatures, geology,

proximity to roadways, ground depth, previous

incidents, etc. – multiplied by the kilometers of

pipe in the ground. The more data these systems

receive and analyze, the better they can project

pipeline failures and proactively recommend

remediation, repairs, replacements, and

relocations.

For utilities, capturing this data is not as easy

as one might think. “Today, when you need to

operate on a pipe, you may not know exactly

where it’s located or what it’s made of,” says

Philippe Simon, a gas utility and distribution

expert with T.D. Williamson (TDW). “Often,

operators can’t formally acquire this information

until a line is excavated for maintenance or

relocation.”

This isn’t to say that some pipe data doesn’t

exist. In fact, about 20 years ago, utilities started

more consistently compiling data, but most of

that information was logged on paper and filed

away in metal cabinets. In other words, it doesn’t

exist in a neatly structured, easy to access data

warehouse with a smooth graphic user interface

and smart query function.

Step By Step

Utilities continue to embrace modeling software,

which evolves on an almost monthly basis. And

with each day there is an opportunity to capture

and store even more data about their lines.

Gaz de France, which owns several hundred

thousand kilometers of distribution pipelines across

the globe, is leading the industry in its commitment

to data capture and input. “With so many

kilometers of existing pipe, to say nothing of the

thousands of kilometers being laid every year, it’s safe

to say that Gaz de France’s data input is perpetual,”

explains Simon. “And Gaz de France, and its

customers, will reap the benefits of such a significant

investment.”

From here, the industry expects to see a new

level of pipeline technology that does more than

analyze input and project potential failures: it’s

looking forward to solutions that also allow utilities

to monitor their pipe systems in real time. This

kind of technology could work hand in hand with

existing solutions, meaning utility companies

would continue to rely on predictive software to

help prevent leaks, and they would leverage new

technology to alert them, in real time, to leaks as

they occur.

Tremendous Opportunities

Although integrated, real-time leak detection

will be a reality one day, gas utilities must meet

customer expectations today: increased safety and

reliability. And they will continue to depend on

trusted leak detection technologies from companies

like GAZOMAT™, a subsidiary of TDW, whose

offerings help utilities detect and characterize leaks,

and determine the appropriate level of response.

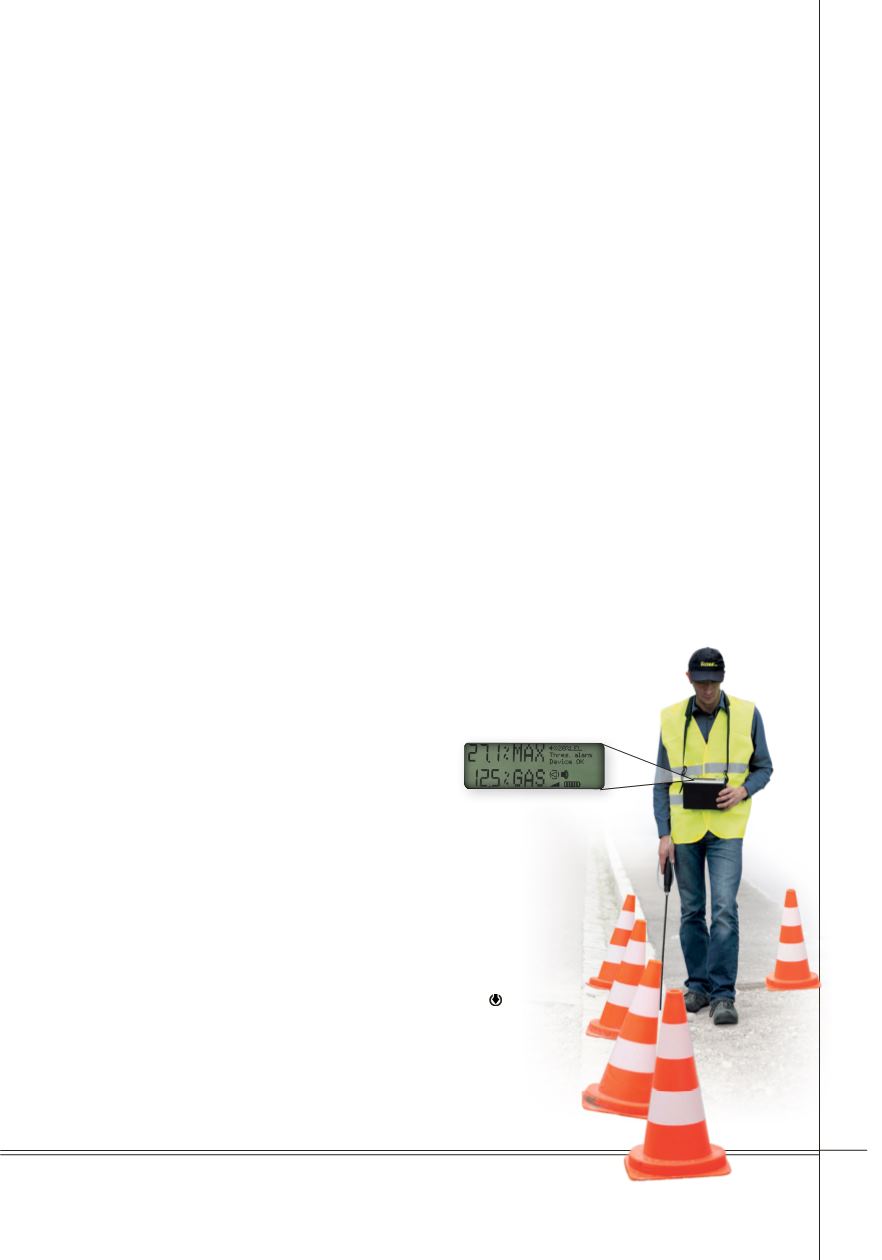

“Through recent advances in leak detection

technology, like the portable Catex™ 3-IR Analyzer,

operators can gather and correlate a wealth of leak

information,” says Simon. “They can also more

accurately assess the risk of a leak or accident.

And since the software prioritizes

attention and investment based on

risk severity, the utility’s efficiency

is significantly increased.”

It’s a powerful affirmation

of the industry’s commitment

to progress, that – even

after more than 100 years

– leak projection and

detection technologies

are still improving,

and faster than ever

before.