5

I N N O V AT I O N S • V O L . V I I , N O. 4 • 2 0 1 5

A TECHNICAL NOTE ON THE STATE OF NDE

Good pipeline integrity management practices are critical to ensure safe

operation. Current practice for condition assessment is to combine data from one

or more inline inspection (ILI) sensor technologies – such as magnetic flux leakage

(MFL) – and one or more ultrasonic measurement modalities with some sampling

of in-ditch, indenter-based hardness testing, and, potentially, a limited number of

cutout and destructive tests.

Ideally, we would like to have a map of local strength parameters at all points

along a pipeline, similar to those for wall thickness, but with values for yield strength,

tensile strength, transition temperature, and fracture toughness. Currently, there is no

technology that can be added to the ILI tool set to provide such data. For decades, the non-destructive measurement

of mechanical properties has been called one of the “holy grails” of non-destructive testing (NDT). Now there is hope

that some technologies may be able (at least partially) to fill this characterization gap and provide material state to

complement defect maps.

Several groups have reported that when current ILI tool data is reviewed, say for an MFL inspection, distinctive

differences in response (as seen in background color or noise level) are seen between sections of pipe with different

mechanical properties. There remain questions regarding the significance and quantification of these differences and

how these indications – together with the future, appropriately optimized sensor packages – could potentially provide

data that can relate to and estimate pipe properties, such as yield strength.

Research is ongoing to identify the

microstructural features of pipeline steels

that are most relevant in determining the

mechanical properties of interest, and

to identify or develop non-destructive

evaluation (NDE) measurement techniques

for characterizing these features, which

can form the basis for in-ditch material

state assessment. Various ultrasonic

and electromagnetic methods are being

evaluated.

For additional information or to offer to

provide samples of characterized pipeline

steel, please contact the Center for NDE,

Iowa State University –

bondlj@iastate.edu.

Leonard J. Bond,

F.AAAS., F.Inst.P.

DIRECTOR – CENTER FOR NONDESTRUCTIVE EVALUATION,

IOWA STATE UNIVERSITY

Industry Commentary from Around the World

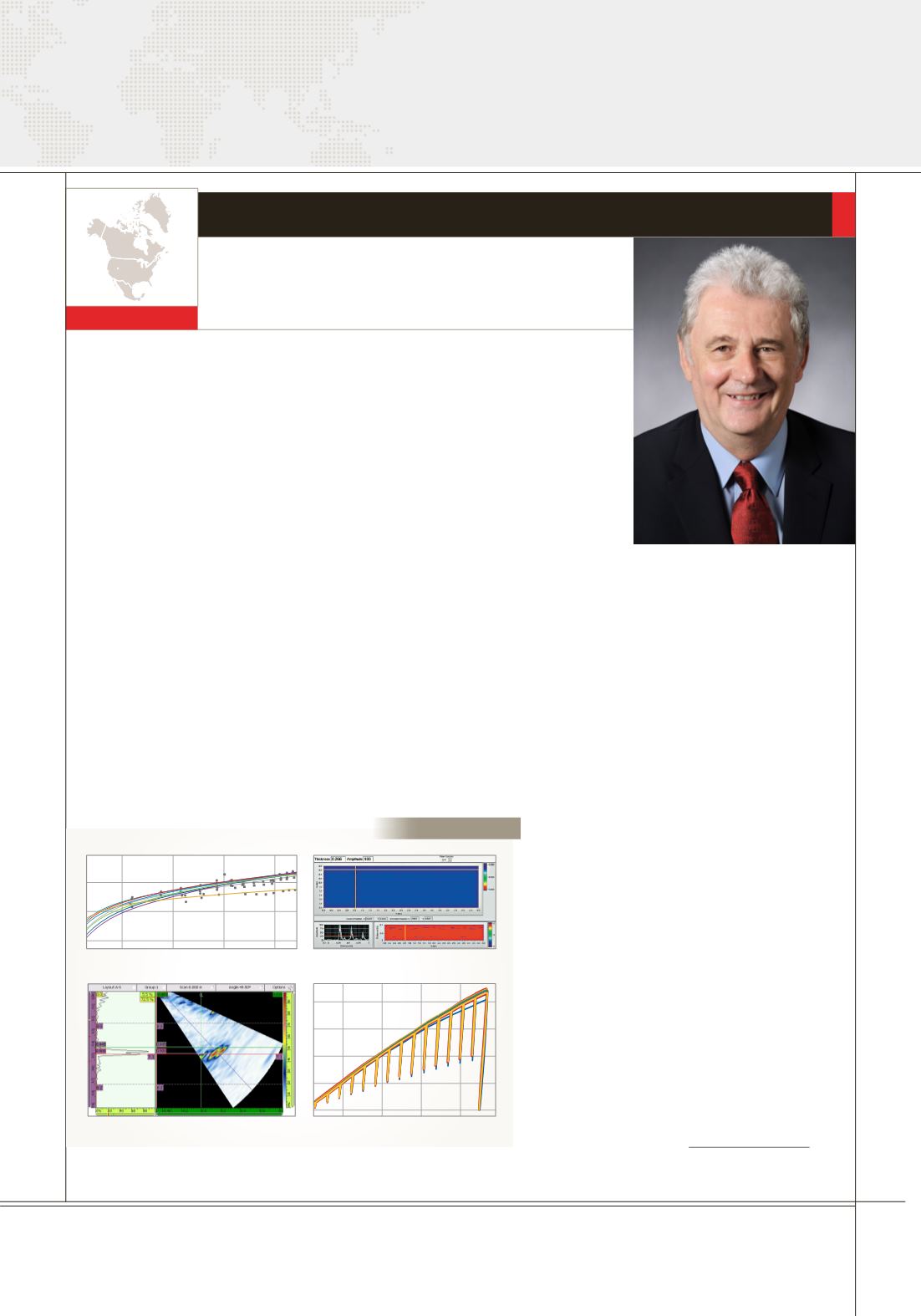

NDE DATA SAMPLES

Yield Strength Data – Stress Strain Curve

Actual Wall Thickness (AWT) Data

Phased Array

Yield Strength Data – Load vs. Depth