10

I N N O V AT I O N S • V O L . V I I , N O. 4 • 2 0 1 5

Offshore operators seek

to bypass hydrotesting

through alternative line

proving processes.

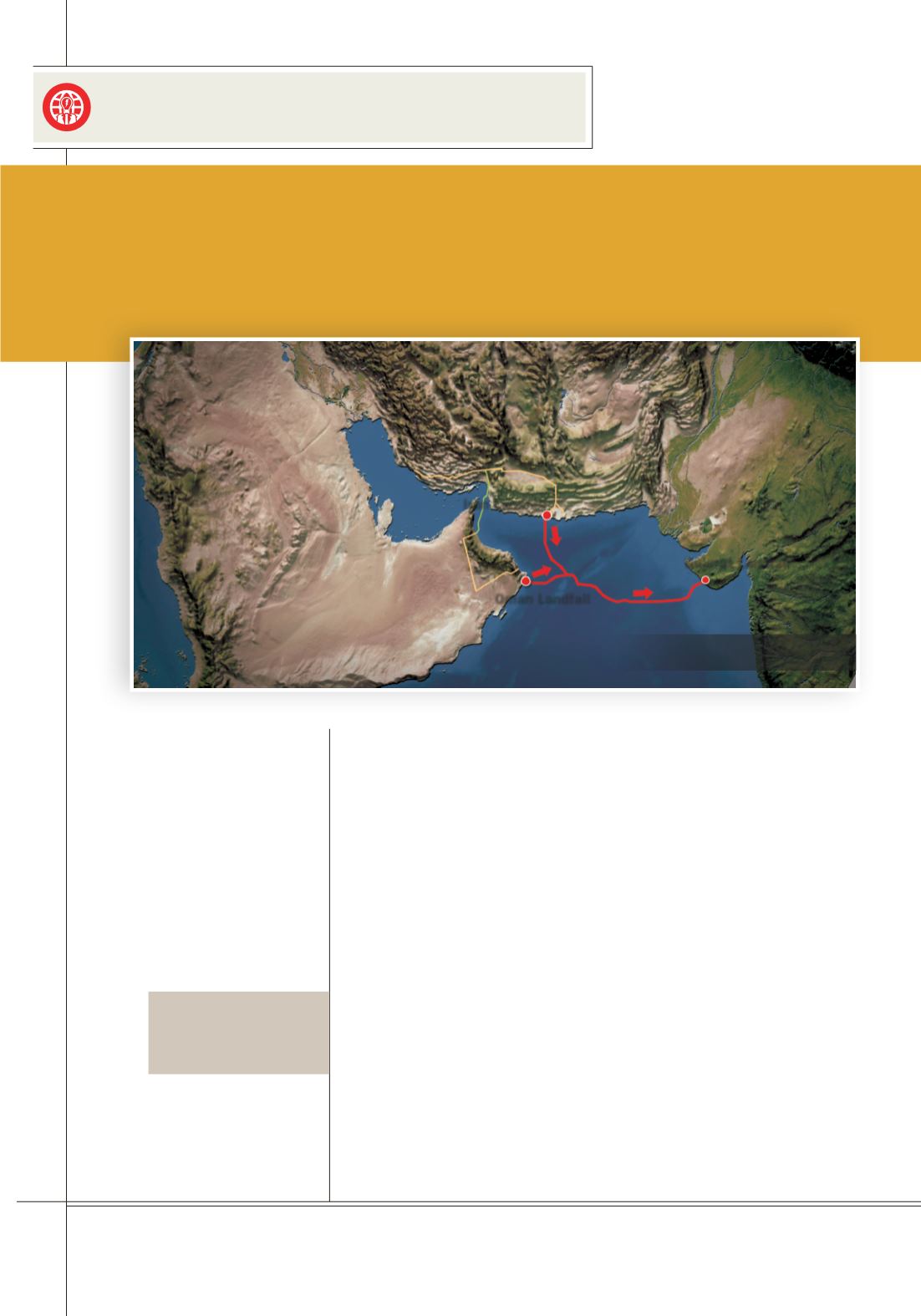

If it is approved by the governments involved, the proposed

US$5.6 billion Oman-India Deep-Water Multipurpose Pipeline Project

(OIDMPP) could become the longest and deepest offshore pipeline in

the world. The massive line will extend 1,600 km (994 mi) from Oman

to India along the bed of the Arabian Sea, moving natural gas and other

petroleum products from the Middle East to India at depths down to

3,400 meters (11,154 feet).

1

It’s an ambitious project, and one that will require meticulous line-

proving measures to identify defects before they can pose a danger to

human safety or cause widespread environmental and economic damages.

Operators typically conduct maximum allowable operating pressure

(MAOP) tests in new oil and gas pipelines by filling the lines with

inhibited seawater and pumping up the pressure to see if leaks or

failures occur. This process, known as hydrostatic pressure testing, or

“hydrotesting,” has been the standard for precommissioning pipelines

since the 1950s, required by regulatory organizations around the globe.

Decades later, hydrotesting is still considered highly effective and

valuable. But imagine the challenges associated with hydrotesting on a

subsea project the scale of the Oman-India line – from locating leaks

to disposing of the half billion liters of chemically inhibited seawater.

More Waivers Could Be On the Way for

DEEPWATER PIPELINE

HYDROTESTING

F U T U R E T H I N K I N G

Oman-India Deep-Water Multipurpose

Pipeline Project (OIDMPP)

Oman Landfall

Gujurat Landfall

Iran Landfall

PAGE 14:

Read more about

hydrotesting in the cover

article TEST AND TEST AGAIN.