sluggish at best – the pipeline ticked off two other

boxes associated with unpiggability: its circa-1970s

age and an internal design with eight acute miter

bends that made it impossible for pigs to navigate,

clean, or inspect the line.

To help overcome this genuine challenge, the

operator contracted pipeline services provider T.D.

Williamson, which provided a multistep solution

that included:

• Installing custom-designed pig

launchers and receivers at strategic

points along the line;

• Removing and replacing miter bend sections

with pipe that could accommodate

cleaning and inspection pigs;

• Performing a gauge pig run to

ensure that cleaning and inspection

tools could negotiate the pipeline;

• Using progressing cleaning

techniques to clean the line with 24

specially selected cleaning pigs;

• Inline inspection using high-

resolution tools: deformation

(DEF) technology to define any

geometric anomalies, Gas Magnetic

Flux Leakage (GMFL) technology

to locate corrosion, and the XYZ

Inertial Measurement Unit for

GPS pipeline mapping;

• Data validation and analysis.

Because the right pigs were

selected for each stage of cleaning,

the pipeline was in pristine condition

before the inspection runs occurred.

This meant that the inline inspection

tools could deliver the highest

quality data – information the

operator is using to plan repairs and

other work.

But ensuring integrity wasn’t the

only benefit the operator achieved from

the pigging program.

According to pigging solutions

expert Stephen Miska, the pipeline is now more

productive (i.e., profitable), and its operational life

span has been enhanced.

“The pigging program maximized the amount

of product that could flow through the system and

lowered associated production costs,” Miska explains.

“And as far as their life span, even for pipelines that

are 30, 40, or 50 years old, with regular cleaning,

inspection, and corrosion control, there’s no known

limit to how long they can operate.”

Like in Don Quixote, it’s futile to fight

invented enemies. But as the Polish pipeline

example suggests, picking battles wisely can create

prodigious results.

WHICH PIG TO PICK FOR THE CLEANEST PIPELINE?

I N N O V AT I O N S • V O L . V I I , N O. 4 • 2 0 1 5

7

Not only can a clean pipeline keep you in

compliance, it can also improve throughput and

corrosion control, which increases revenue and

reduces the risk of leaks or ruptures. But how do

you know which pig to select?

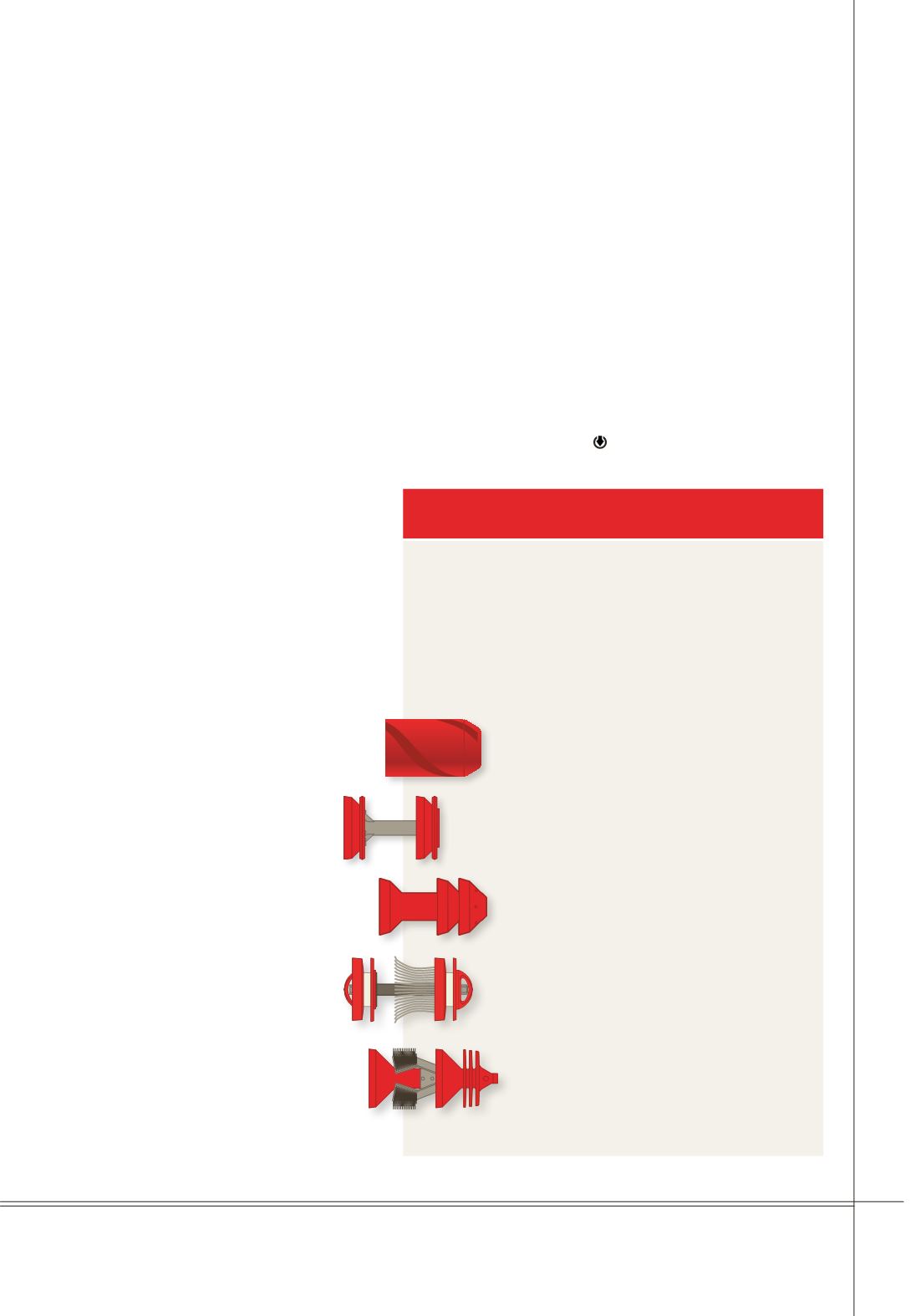

SPRING-MOUNTED BRUSHES

remove

hard internal deposits like scale and

corrosion.

DISCS

can push out solids, including

debris, and can run bi-directionally.

ALL-URETHANE WAX-CUTTING BLADES

can remove soft deposits such as

paraffin and sludge.

Although mainly used to seal the pig

inside the pipeline,

TIGHT-SEALING

CONICAL CUPS

also provide some

cleaning and dewatering.

CUSTOM CONFIGURATIONS

can solve

specialized cleaning issues: Pig length

can be altered, and cups and discs

can be rearranged in specific series. In

addition, certain pigs can be modified

for very heavy wall pipe or outfitted with

transmitters for tracking purposes.