1

I N N O V AT I O N S • V O L . V I I , N O. 4 • 2 0 1 5

2 |

EXECUTIVE OUTLOOK

Upping our game in the oil

and gas industry

4 |

GLOBAL PERSPECTIVE

Industry commentary from

around the world

6 |

TECHNOLOGY FOCUS

Developing the right plan to

overcome "unpiggable"

8 |

SAFETY MATTERS

Unpacking social license and

building relationships

10 |

FUTURE THINKING

Promoting alternative line

proving processes

12 |

MARKET REPORT

Benefiting from a low oil

price environment

20 |

TOUCHPOINTS

Pipeline Events, Papers

and Conferences

28

|

BY THE NUMBERS

The 5 Whys of Pigging

Automation

14 |

Test and Test Again

Providing a more comprehensive understanding of pipeline

integrity by combining tried-and-true pressure testing with

leading edge inline inspection technology.

22 |

Loss Prevention and Insurance

Realizing the added benefits of loss prevention programs

as they help optimize insurance costs.

D E P A R T M E N T S

EDITOR-IN-CHIEF

Jim Myers Morgan

MANAGING EDITOR

Waylon Summers

ART DIRECTOR

Kat Eaton

DESIGN PRODUCTION

Mullerhaus.netDIGITAL PRODUCTION

Jim Greenway, Ward Mankin

PHOTOGRAPHY

Adam Murphy, Scott Miller

T.D. Williamson

North and South America +1 918 447 5000

Europe/Africa/Middle East +32 67 28 3611

Asia Pacific +65 6364 8520

Offshore Services +47 5144 3240

www.tdwilliamson.comWant to share your perspective on anything in our magazine?

Send us an e-mail:

Innovations@tdwilliamson.comV O L . V I I , N O. 4 • 2 0 1 5

Innovations

™

Magazine

is a quarterly publication produced by T.D. Williamson.

®Registered trademark of T.D. Williamson, Inc. in the United States and other countries. ™ Trademark of T.D. Williamson, Inc. in the United States and other countries.

© T.D. Williamson, Inc. 2015 Reproduction in whole or in part without permission is prohibited. Printed in the United States of America.

14

10

22

28

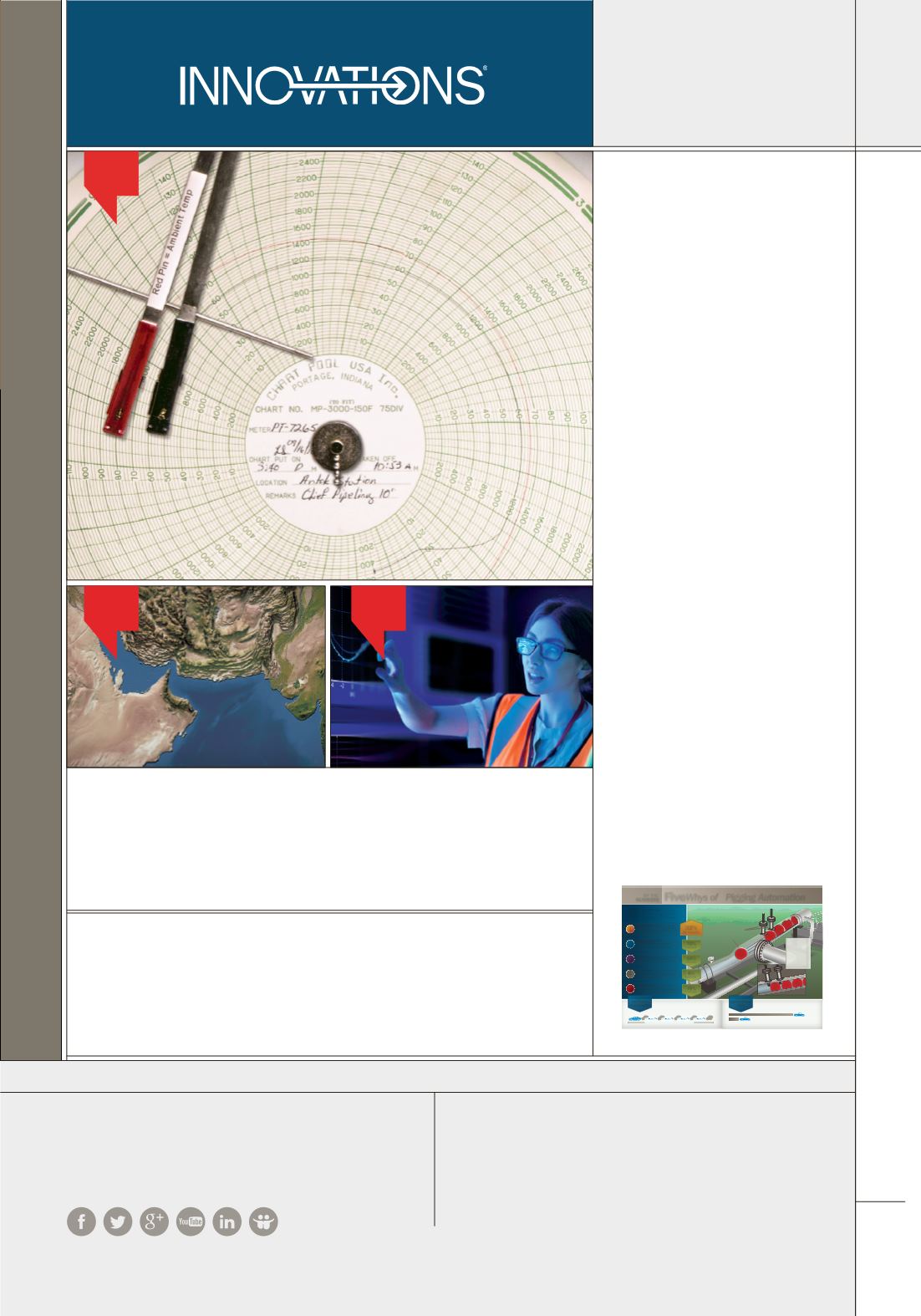

Phases

Four

BYTHE

NUMBERS

of

PROGRESSIVEPIGGING

29

INCREASE and REDUCTION

in just the right

areas. Follow this example of an Eagle Ford shale

play operator as it implements pigging automation to

increase its system

efficiency

while lowering

cost

.

As the operatorwas able to preloadmultiple spheres, program and

release them automatically, it required fewer site visits by its technicians,

whichmeant

less drive time and reducedoperational risk.

After one year of implementing pigging automation, the operator

reduced itsmethane emissions

equivalent to the emissions

output of 558 passenger vehicles over the same time period.

85% REDUCTION

IN HOURS/MILEAGE

THROUGHPUT

i

ncreased due to greatly

enhanced flow efficiency, as a result ofmultiple

pig/tool loading options, automated release, and

consistent liquids removal.

HEALTH,SAFETY,AND

ENVIRONMENTAL

savings realized as

driving frequency and operational injury risks

are reduced;methane emissions lowered.

PERSONNEL

reallocation realized as fewer

field technicians are required to launch and

receive spheres, pigs, and inspection tools.

OPERATIONAL

costs lowered by reduced

fuel and power consumption,maintenance,

and risk of plant shutdown; less valve cycling

resulting in longer valve life.

REGULATION

compliance cost proactively

reduced, such asmeeting the criteria for the

Environmental Protection Agency's (EPA) voluntary

NaturalGasSTARMethaneChallenge Program.

70%

reduced

64%

reduced

4%

reduced

39%

reduced

reduced

methane

emissions

32%

increased

after

automation

before

automation

DUAL

LAUNCH PINS

SPHERE

Does not fully include fuel

& power savings.

558 PASSENGER VEHICLES DRIVING AVERAGEMILES OVER ONE YEAR

reduced

operational

risk

AUTOMATED LAUNCH

So how is pigging actually

automated?

»

Loadmultiple spheres

at one time

»

Programmable logic

controller

»

Hydraulically operated

release system

Automation also offers the

added benefits of reduced

closure door operation and

valve cycling.

1

4

5

2

3

W ysof

Pigging Automation

ive