I N N O V AT I O N S • V O L . V I I , N O. 2 • 2 0 1 5

4

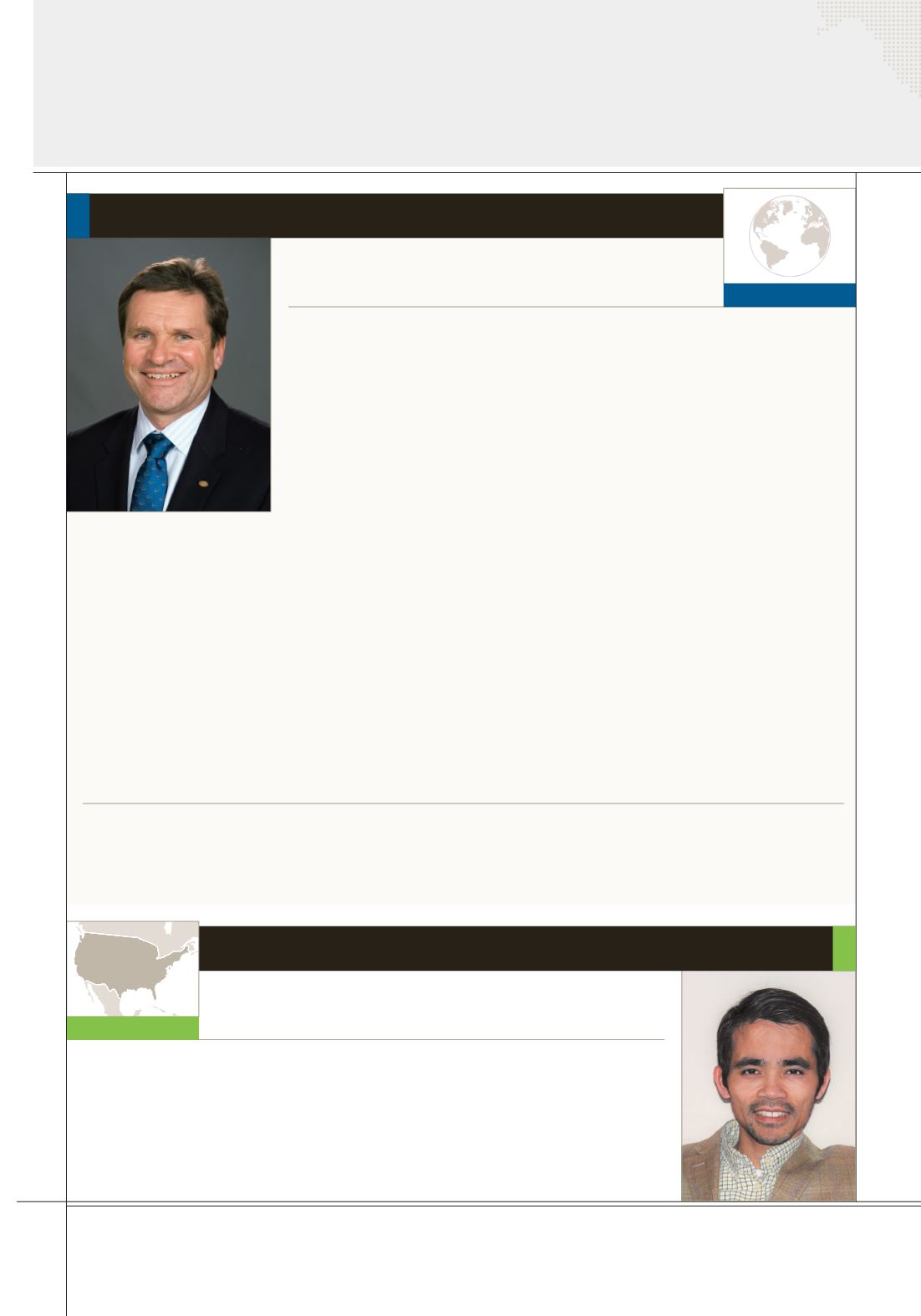

TU TRAN

OPERATION RESEARCH ANALYST, ENERGY INFORMATION ADMINISTRATION

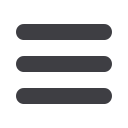

GROUNDBREAKING REPORT ON CORROSION

NACE International is compiling the International Measures of Prevention, Application and

Economics of Corrosion Technologies (IMPACT) study, a groundbreaking report on the

costs of corrosion for many industries and nations worldwide. With 16 research partners

in nine countries, this study will provide the most comprehensive data ever recorded on

the financial impact of corrosion on the world’s largest economies, to include economic

models and templates.

In the early part of 2015, participating research partners began the data collection process.

Once all data is submitted to NACE International, it will be combined and analyzed to provide a

global view of the costs of – and solutions to – the threats of corrosion.

The last time this kind of research was done (2002), it was commissioned by the U.S.

Congress and assigned to the Federal Highways Administration (FHWA). For the past decade it has served as a valuable resource;

however, it only focuses on U.S. assets and didn’t address indirect costs. The IMPACT study will include global data and examine

indirect costs.

Each year, there are increasing reports on the rising challenges of aging, poorly maintained infrastructure. For example, in the

United States, hundreds of billions of dollars are spent annually on mitigating corrosion of infrastructure, such as gas and liquid

pipelines, railroads, and hazardous materials storage. In addition, corrosion has a high cost in production and manufacturing sectors,

such as oil and gas exploration and production, petroleum refining, and petrochemicals.

The FHWA study indicated that a savings of as much as 30 percent is possible through the use of corrosion control technology

that was available even 10 years ago, but the study was unable to specifically identify the cost differences between prevention,

repair, and replacement of assets. The IMPACT study will be the first study to provide that data. It will demonstrate the usefulness

of corrosion control methods and the long- and short-term affordability of those methods. And it will go beyond just the costs

associated with corrosion in a collection of case histories and industry best practices.

Research partners for this study include: Chinese Academy of Sciences, Japanese Society of Corrosion Engineers, Australasian Corrosion Association

(ACA), Saudi Aramco, American Water Works Association (AWWA), Federation of Indian Chambers of Commerce and Industry (FICCI), DECHEMA Institute,

U.S. Department of Defense, International Union of Painters and Allied Trades (IUPAT), U.S. Department of Transportation Pipeline and Hazardous

Materials Safety Administration (PHMSA), U.S. Environmental Protection Agency (EPA), U.S. Federal Highways Administration (FHWA), Petronas, Exova,

Association of State and Territorial Solid Waste Management Officials (ASTSWMO), and Northern Area NACE International representing Canada.

Bob Chalker

CHIEF EXECUTIVE OFFICER, NACE INTERNATIONAL

Global

Perspective

THE STATE OF BIDIRECTIONAL NATURAL GAS PIPELINE CAPACITY

32 Percent Of Natural Gas Pipeline Capacity Into The Northeast Could Be

Bidirectional By 2017 —

Spurred by growing natural gas production in Pennsylvania, West

Virginia, and Ohio, the U.S. natural gas pipeline industry is planning to modify its systems to

allow bidirectional flow to move up to 8.3 billion cubic feet per day (Bcf/d) out of the Northeast.

As of 2014, the industry had the capacity to transport 25 Bcf/d of natural gas from Canada, the

Midwest, and the Southeast into the Northeast. In addition to these bidirectional projects in the