I N N O V AT I O N S • J A N U A R Y - M A R C H 2 0 1 4

18

technology. It’s one of the only crack detection

technologies you can run in a natural gas

pipeline to detect cracks without removing the

natural gas. The alternative is hydrostatic testing,

in which an operator has to remove the gas from

the line and run a water pressure test to see if

the pipe springs a leak. Although still considered

the gold standard for pipeline operators, this

hydrostatic testing is expensive and disruptive to

the flow of gas.

EMAT has been tentatively looked to as an

acceptable alternative, but the technology has

been somewhat disappointing. TDW’s Director of

Integrity Technology Jeff Foote, says, “Proponents

of EMAT have long promised things that their

technology just couldn’t deliver.”

EMAT is an ultrasonic technology. It works by

introducing an ultrasonic signal into the pipeline

wall, causing it to vibrate. By reading the signals

that bounce back to the receivers, theoretically,

analysts can see where the waves have had a little

hiccup on their pathway around the pipeline. Such

hiccups – or deformities in the wave patterns – can

tell analysts where the cracks may be forming.

In the field, however, the technology has been

plagued with issues. For one, the transmitting

and receiving sensors are notoriously fragile. In

most EMAT systems, the sensor development was

rooted in applications designed to be stationary –

they weren’t built to be dragged along the inside of

the rugged and hostile environment found within

a pipeline. These sensors are so unsuited for this

environment, in fact, that it’s not unheard of for

sensors to fail completely before a run is complete.

Not only does that compromise the data, but it

forces the operator to replace the sensors and run

the tool again – a costly proposition.

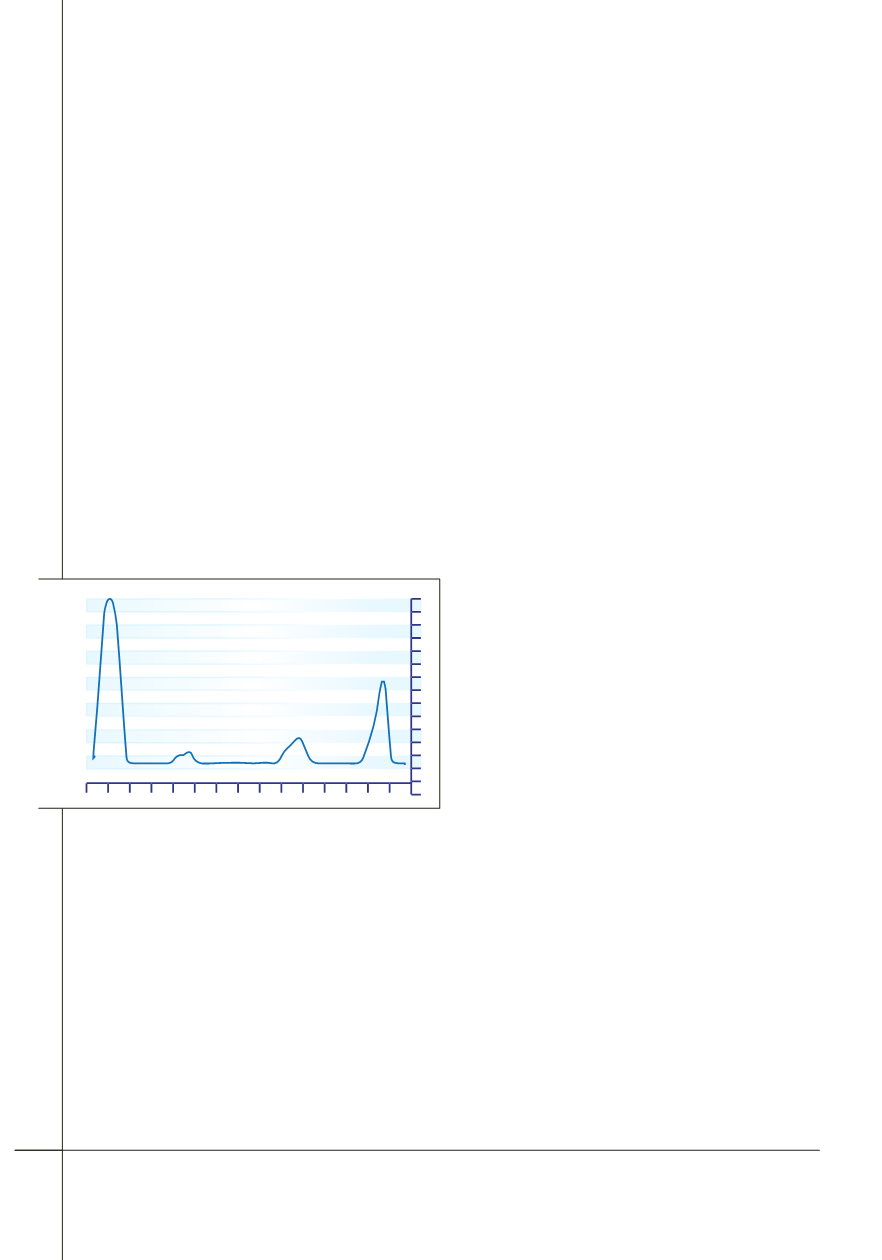

EMAT is also sensitive to noise. It’s an ultrasonic

test, after all. It depends on clear, clean wavelengths

to run the circumference of the pipeline. Noise can

interfere with that – like noise from the rest of the

electronics on the tool. So EMAT results have been

traditionally difficult to read.

The tools are also big. Some tools require as

many as 48 sensor sets to image the pipeline. That

means that, in most cases, EMAT can’t even be used

in lines that are less than 12 inches in diameter. That

negates its use in 50 to 60 thousand miles of small

gathering lines in the United States alone.

Bottom line, although EMAT has always

seemed like a good idea, prior EMAT technology

just hasn’t lived up to expectations.

Now, TDW thinks it may have cracked the code.

Although TDW isn’t ready to suggest that its

EMAT is a replacement for hydrostatic testing

for cracks, the new EMAT technology that TDW

added to their MDS system does greatly improve

the system’s ability to detect and prioritize cracks –

much like the hook cracks that caused the

Mayflower spill.

THE RIGHT ANGLE

Smaller, hardier, clearer results– TDW’s SpirALL

®

EMAT technology solves many of the current

issues with prior EMAT technology. Perhaps the

most important feature of SpirALL

®

EMAT is

its helical arrangement of sensors. This patented

helical, or spiral, sensor alignment allows the

ultrasonic signal to be transmitted at a 51 degree

angle relative to the pipe’s interior.

Having just the “right” angle amplifies the

signal-to-noise ratio, so that the wave patterns

traveling from transmitter to receiver can be heard

loud and clear. Combine that with ultra-sleek,

low-noise electronics, and you’ve got a pretty

impressive image on your crack-detection report.

In addition, because of the arrangement of

the sensors, fewer sensors are needed to provide

more robust information. TDW uses only eight

receivers to image the pipe, as opposed to the

High signal-to-noise ratio