I N N O V AT I O N S • J A N U A R Y -

M A R C H 2 0 1 4

11

The world is getting older, and so is our

infrastructure. According to the U.S. Pipeline and

Hazardous Material Safety Administration (PHMSA),

in the United States alone, nearly half of all interstate

transmission mileage was installed between 1950 and

1970. That translates into hundreds of thousands of

miles of 60-year-old lines crisscrossing the country.

Like the age of our average citizen, the age of our

average pipeline is increasing. Somewhat surprisingly,

the technology called to task to address both issues is

markedly similar.

For instance, doctors can prescribe better-fitting,

more customized splints and braces because of newer

materials used to create them. Cardiologists can offer

patients less invasive coronary bypass procedures, and

physicians from virtually every medical specialty now

rely on non-invasive imaging tools such as MRIs and

ultrasounds. Many of the same advances are being

used in pipeline engineering: advances in material

science help keep our pipe joints strong, “bypass”

STOPPLE

®

operations keep pipelines flowing as key

maintenance is performed, and pipeline integrity

testing is rooted in the same imaging technology

used every day in hospitals.

It’s amazing that seemingly niche techniques are

actually so ubiquitous.

AUTOMATING TREATMENT

Let’s begin with pigging. As we see a projected

increase in new gathering lines in the years ahead, so

too will we see an increase in lines that are piggable.

Reasons vary, including anticipating regulatory

action by PHMSA that calls for gathering line

integrity inspections – integrity inspections can only

be performed on piggable lines.

TDW has developed and is testing the

SmartTrap

®

Automated Sphere System, or

AutoSphere, an automated pig launcher that

deploys spheres to clean lines daily so that liquids

and debris can be removed, production optimized

and NGL condensates extracted. It uses the

same Programmable Logic Controller (PLC) –

an automation technology – found in TDW’s

AutoCombo system, used in pigging trunk lines.

Operating much like the pumps that deliver

pre-measured doses of insulin or chemotherapy

drugs, the PLC allows users to program the remote

automated launch of seven to ten spheres sequentially

at designated times and intervals. Benefits to using

automated pigging launchers include improved

routine maintenance of the lines, as well as avoiding

costly operating interruptions caused from the

buildup of impurities.

SEEING IS BELIEVING:

ADVANCED IMAGING TECHNIQUES

As the medical community has increasingly relied on

advanced imaging techniques

for better detection and

treatment, so too,

has the pipeline

industry. One

of the earliest

innovations in

this category was

the inspection

pig. Fairly crude

by today’s

standards, the

early fleet of inspection pigs gave operators their

first real glimpse inside a pipeline. This technique

provided never-before-available information about

the integrity of their lines. Operators received

information about dents, deformations and other

potential problems that were electronically scrolled

on paper rolls.

Because of automation advancements, improved

access and other technology developments evolving

at breakneck speeds, today’s “smart pigs” perform

and deliver results at previously unimaginable levels.

Consider Magnetic Flux Leakage (MFL), for

example, which also has a feature in common with

a medical imaging counterpart, the MRI. Both

>

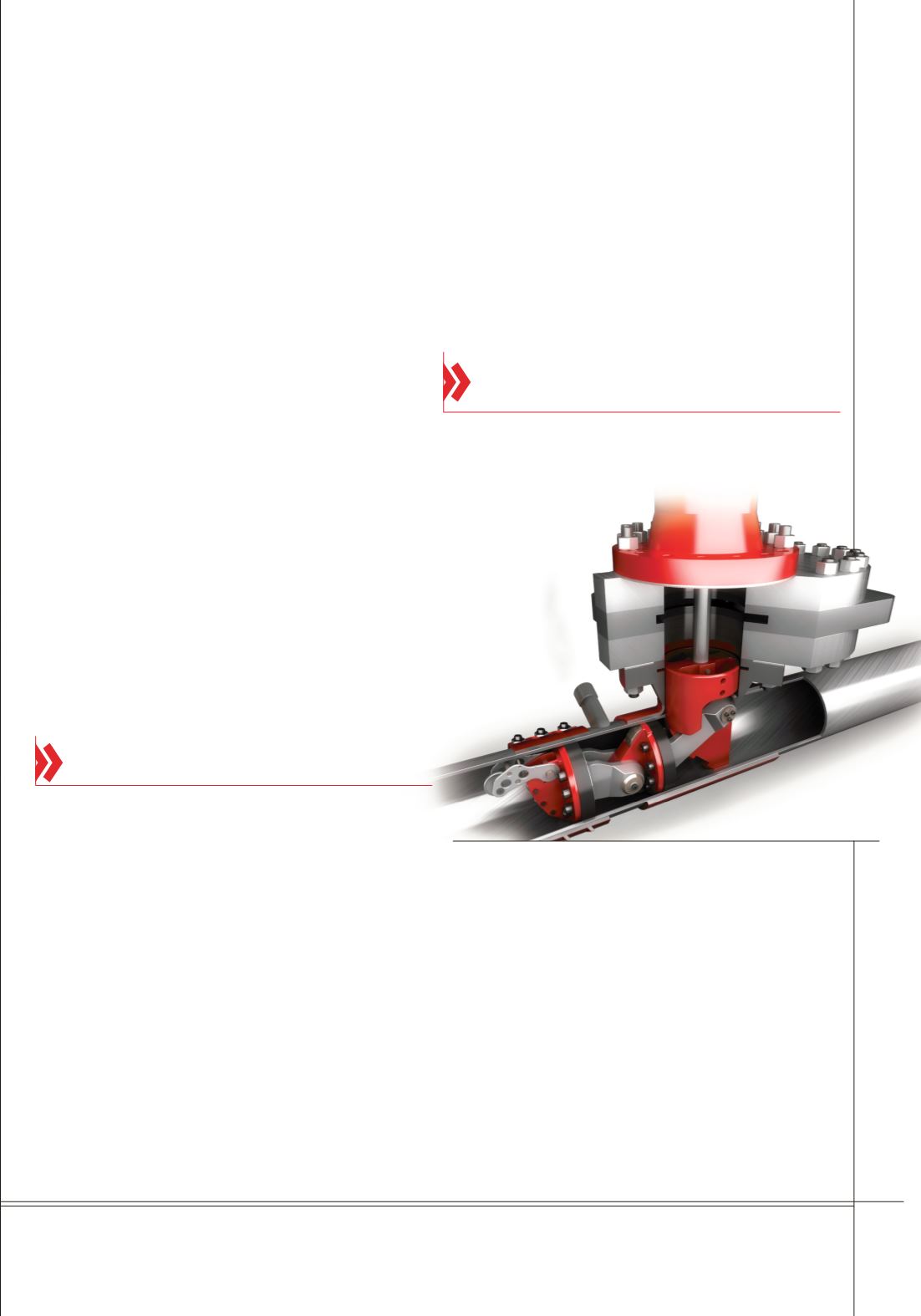

STOPPLE®Train Plugging System