process as tiny anomalies near the pipe’s seam – an area susceptible

to problems in all pipelines. The micro-cracks, formed during

manufacturing, can eventually grow into larger hook cracks, which

can then grow into a full-blown disaster.

However, as ExxonMobil’s spokesperson Aaron Stryck told the

Toronto Star, the results of the inline inspection showed the pipe’s

defects to “be benign and not in need of repair.”

Clearly, there is a need for better inspection techniques.

FINDING THE HIDDEN DANGER

Hook cracks like the ones that doomed the section of the

Pegasus pipeline aren’t the only types of pipe defects that

cause failures. Gouging, mechanical stress, hard spots,

coating disbondment, toe cracks, fatigue cracks, stress cracks,

incomplete fusion, preferential seam corrosion, hydrogen-

induced cracking and good old-fashioned dents are all cause

for concern.

A standard pipeline inspection may uncover thousands of

anomalies. It’s neither practical nor necessary for a pipeline

operator to dig up each one of these after every inspection.

Many of the anomalies are, indeed, benign. But which ones

are important?

There are several ways to analyze the severity of a pipeline

defect. Obviously volume – depth, length and width of the

anomaly – is important. The type and location of the anomaly

is also critical: For example, anomalies by the weld seams

can be more severe. Finally, interacting threats must be taken

into account. While metal loss by itself may not be a big deal,

metal loss associated with a crack in a seam could be

an emergency.

There is a dire need for pipeline integrity inspections not

only to report each anomaly, but to give operators the data they

need to prioritize anomalies correctly.

A STRING OF TOOLS

Operators traditionally use a variety of technologies for inline

inspections. Each technology is adept at finding certain types

of flaws.

Deformation (DEF), for example, is good at detecting dents.

Axial Magnetic Flux Leakage (MFL) is good for volumetric

metal loss, like corrosion.

SpirALL

®

MFL (SMFL) is good for narrow axial anomalies,

like finding crack-like defects within the weld seam.

Low Field MFL (LFM) is excellent for pinpointing

mechanical stress and hard spots.

And Electromagnetic Acoustic Transducer (EMAT) is good

for cracks. (

Or not so good, depending on whom you talk to, but

I N N O V AT I O N S • J A N U A R Y - M A R C H 2 0 1 4

16

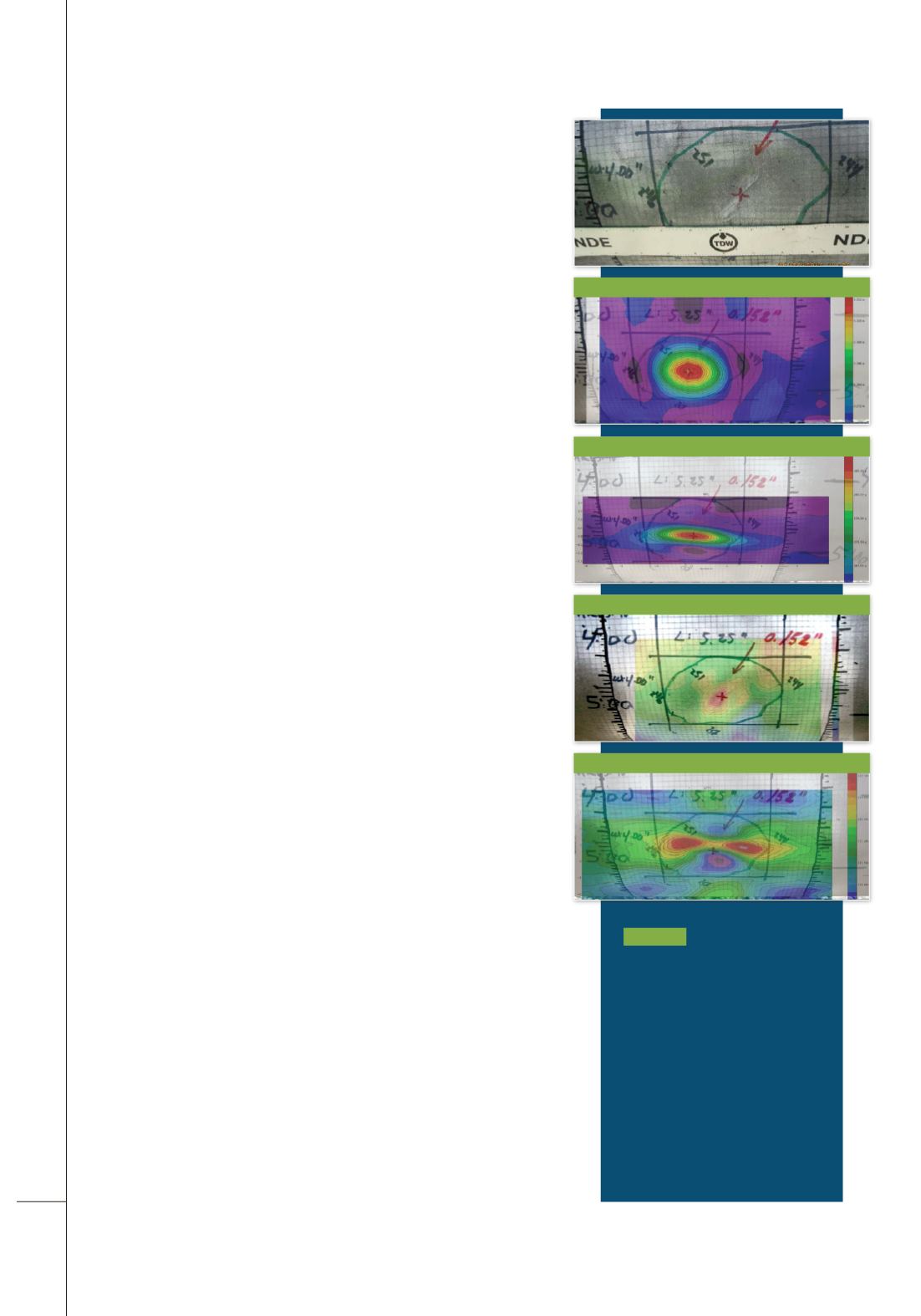

Figure 1.

Mechanical Damage

from an MDS inspection. Less-

than 1% dent with volumetric

metal loss identified in the Axial

Field (High Field), confirmed in

the SMFL data as having some

volumetric characteristics, but

also narrow axial; re-rounding

clearly identified in the Low-Field

MFL. A <1% depth dent, in

many cases overlooked from a

severity standpoint, identified as

a “priority 1” through use of the

MDS platform, and found to have

associated cracking.

Deformation

Low Field MFL

High Field MFL

SpirALL® MFL