we’ll get to that later.

)

Operators choose which technologies to run,

and can run them on different dates, or on the

same date back-to-back. In some of the latest

iterations, operators can run multiple technologies

as part of an integrated platform.

This “stringed” approach to running pipeline

integrity tools provides a better solution for a

few reasons.

First, you get data that is measured at a single

point in time. As T.D. Williamson’s Manager of

New Technology Development Davin Saderholm

puts it, “With single technology tools you don’t

get a complete data set aligned in time and space.

So, you can’t say with certainty that the anomalies

you are seeing are at the exact same spot. When

you run the tools separately, you can say, ‘in this

joint, we have a dent with a crack and a gouge,

and I think it’s in the same place,’ versus, with

technologies run together, you know it’s in the

same place.”

Secondly, when multiple technologies are

run on a single platform, you have the option

to build the system around a single data

processor or CPU, and use a single software to

analyze all of the data simultaneously. When

run separately, each on its own software

platform, analysts have to spend countless

hours combining multiple sets of information

displayed by multiple sets of programs. Having

a single software display the data makes data

analysis infinitely easier, reduces the rate of

human error, and can ultimately be more cost

effective for the operator as fewer man hours are

required to analyze the information.

Thirdly, running the multiple technologies in a

single run means less labor, less risk of injury, and

less time spent on inspections.

Finally, the platform approach to running

tools gives operators the most critical information

they need to prevent tragedies – the data

to prioritize pipeline flaws. When tools are

run separately, you may get a single piece of

information that, in and of itself, doesn’t really

sound any alarms. Let’s say a tool reports a

1 percent dent. Without additional data, the

operator may consider that dent a fairly low-risk

anomaly. But if the operator can see the data from

several technologies side-by-side, he may learn

that the 1 percent dent is actually a longitudinal

gouge, and that because of pressure in the pipeline

that gouge had been re-rounded and bounced

back. All of a sudden that 1 percent dent is

looking a lot worse.

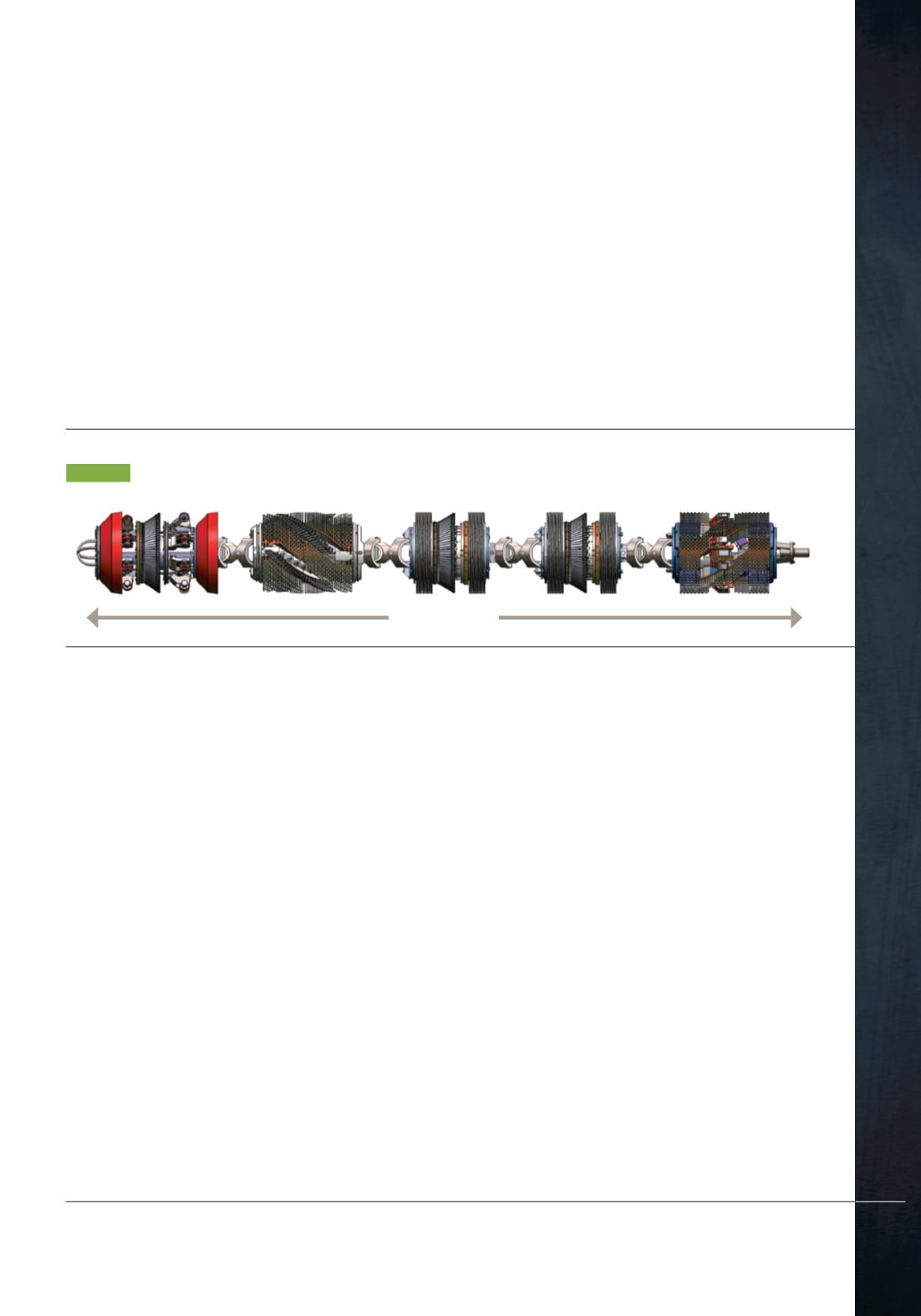

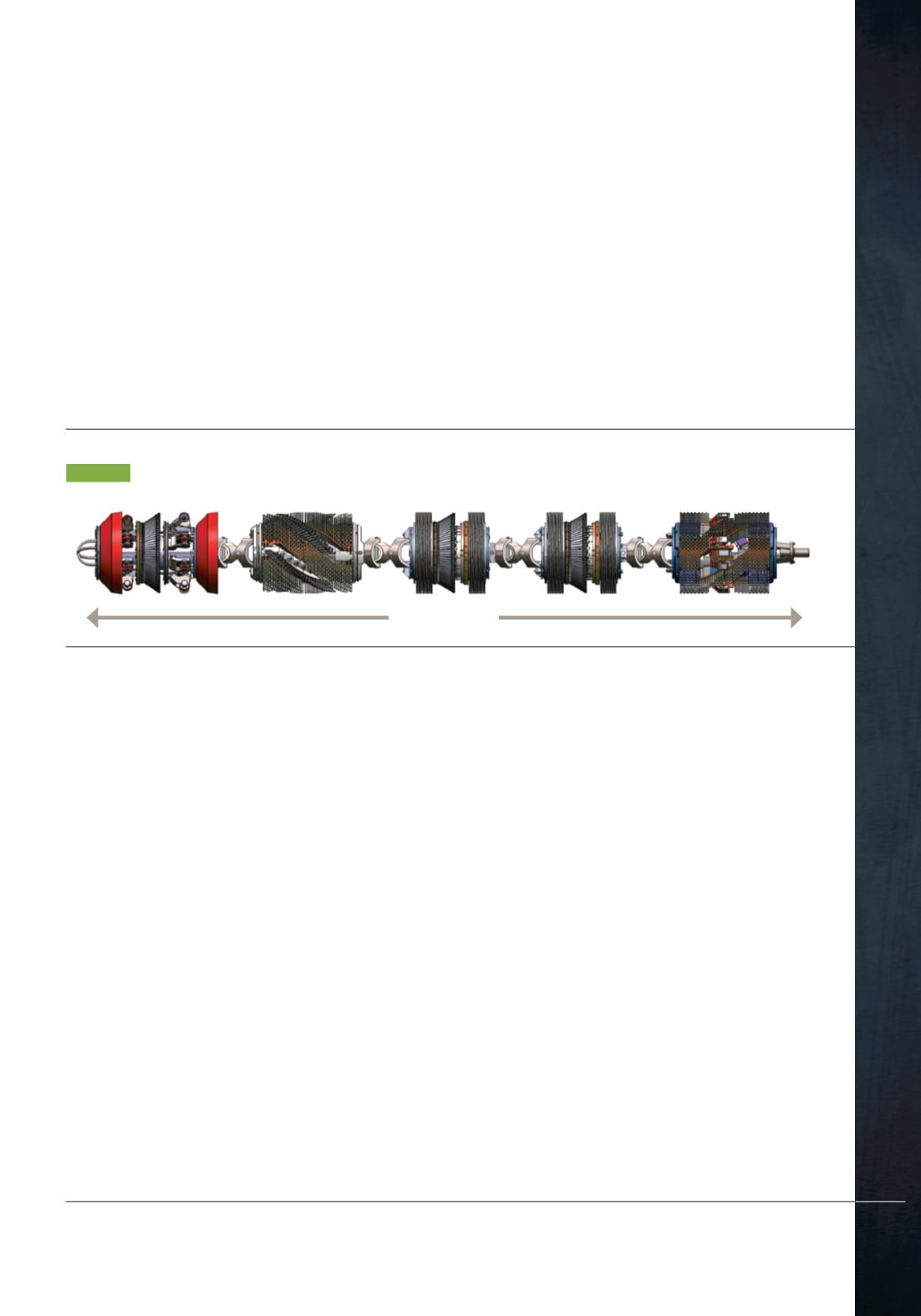

T.D. Williamson (TDW) has one of the most

comprehensive single platform inspection tools

on the market. Their trade name for this tool is

the Multiple Dataset Platform, or MDS for short.

The MDS includes DEF for deformation, Axial

MFL for volumetric metal loss, SpirALL

®

MFL for

longitudinal axis metal loss features, low field MFL

for mechanical properties of steel, and XYZ for

geospatial pipeline mapping.

The company recently added SpirALL

®

EMAT

to detect longitudinal cracks. That’s a big deal.

Cracks are what caused the Mayflower spill.

Cracks are bad.

EMAT’S BROKEN PROMISES

EMAT by itself has been a somewhat debated

I N N O V AT I O N S • J A N U A R Y -

M A R C H 2 0 1 4

C O V E R S T O R Y

17

Figure 2.

24-inch DEF+SMFL+MFL+LFM+EMAT.

17.3 ft. / 5.25 m.