Third-Party Damage: A Problem

That Knows No Boundaries

Jeff Foote, Director, Pipeline Integrity Tech-

nology, at global pipeline services company T.D.

Williamson, has been analyzing third-party

damage for a decade. His interest in the topic

was piqued when he became involved with the

Association of Oil Pipelines, an organization of

pipeline operators in the United States that has

studied the causes of pipeline incidents.

Although the group identified other issues

that contributed to pipeline failure – among them,

structural flaws, fatigue, age, and even operator

error – third-party damage clearly topped their list.

Utility excavation in shared rights of way is a major

source of damage, often occurring when giant

mechanical shovel teeth graze a pipeline’s exterior.

But mechanical shovels aren’t the only potential

source of damage: Even something as seemingly

innocuous as a farmer tilling his field has caused

everything from pipeline dents to explosions.

These are situations that know no national

boundaries.

CEPA, the Canadian Energy Pipeline Association,

points to “accidental damage caused by excavation

and construction around pipelines” as “one of the

greatest single causes of damage to pipelines.”

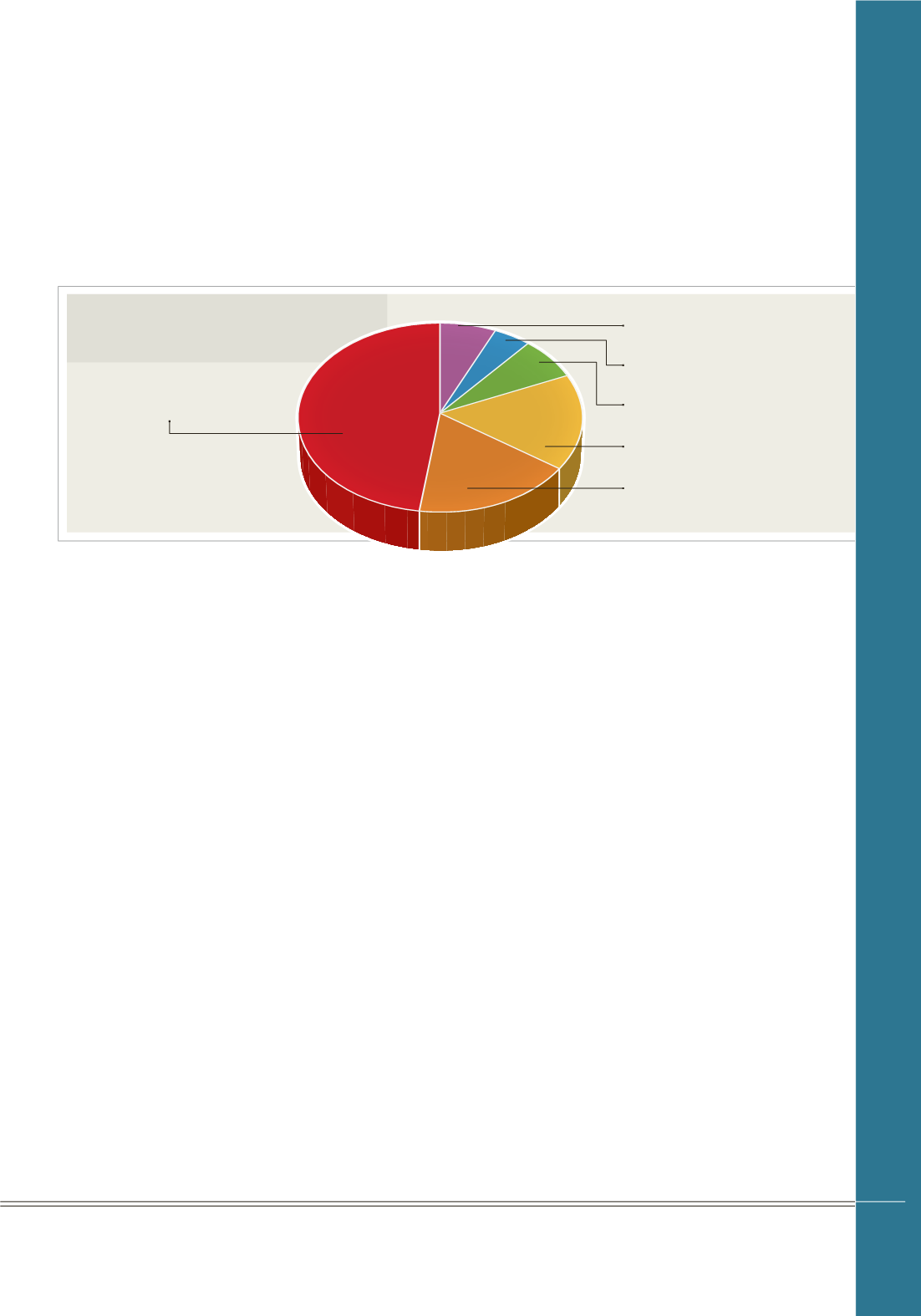

Similarly, the 17 major gas transmission

system operators who comprise the European Gas

Pipeline Incident Data Group (EGIG) report that

by far the greatest cause of loss-of-gas incidents is

external sources.

And in the United States, the Pipeline Hazardous

Materials Safety Administration (PHMSA) calls

“third-parties digging in the vicinity of buried

pipelines the greatest threat to pipeline safety.”

For all of this common concern, there are,

fortunately, widely available damage detection and

repair solutions, including new and innovative

technologies, from detector dogs like Max to

virtual microphones and inline inspection tools.

And each solution has a place in a comprehensive

pipeline integrity program.

On The Scent: Detector Dogs

Go Straight To The Source

The reason a dog can locate gas pipeline leaks is as

plain as the nose on its face: The canine sense of

smell is anywhere from 10,000 to 100,000 times

more acute than ours. For perspective, if we were

talking about sight instead of smell, an object that

a person could see from a half of a kilometer (third

of a mile) away could be seen by a dog 4,800 km

(3,000 miles) away, just as clearly.

But that’s just one of the innate abilities that gives

dogs a leak-locating advantage, says Ron Mistafa.

Not only can dogs be trained to detect

thousands of substances, they can find quantities

of lost product as small as 0.07 ml. Dogs are also

portable and have built-in locomotion, which

makes them capable of inspecting long lengths of

pipe each day. And they’re generally quite quick at

their craft: Mistafa says that one of his dogs found

a leak in a record five minutes.

Dogs also offer spot-on precision. “Where the

dog starts to dig, that’s where the leak is,” Mistafa

explains. “As a result, the operator only has to dig

once to do the repair.”

I N N O V AT I O N S • V O L . V I I , N O. 1 • 2 0 1 5

F E AT U R E S T O R Y

DISTRIBUTION OF PIPELINE

INCIDENTS BY CAUSE

THIRD-PARTY DAMAGE

| 48.4%

OTHER AND UNKNOWN

| 6.6%

HOT-TAP MADE BY ERROR

| 4.8%

GROUND MOVEMENT

| 7.4%

CORROSION

| 16.1%

CONSTRUCTION DEFECT/

MATERIAL FAILURE

| 16.7%

23

Source: EGIG