18

I N N O V AT I O N S • V O L . V I I , N O. 1 • 2 0 1 5

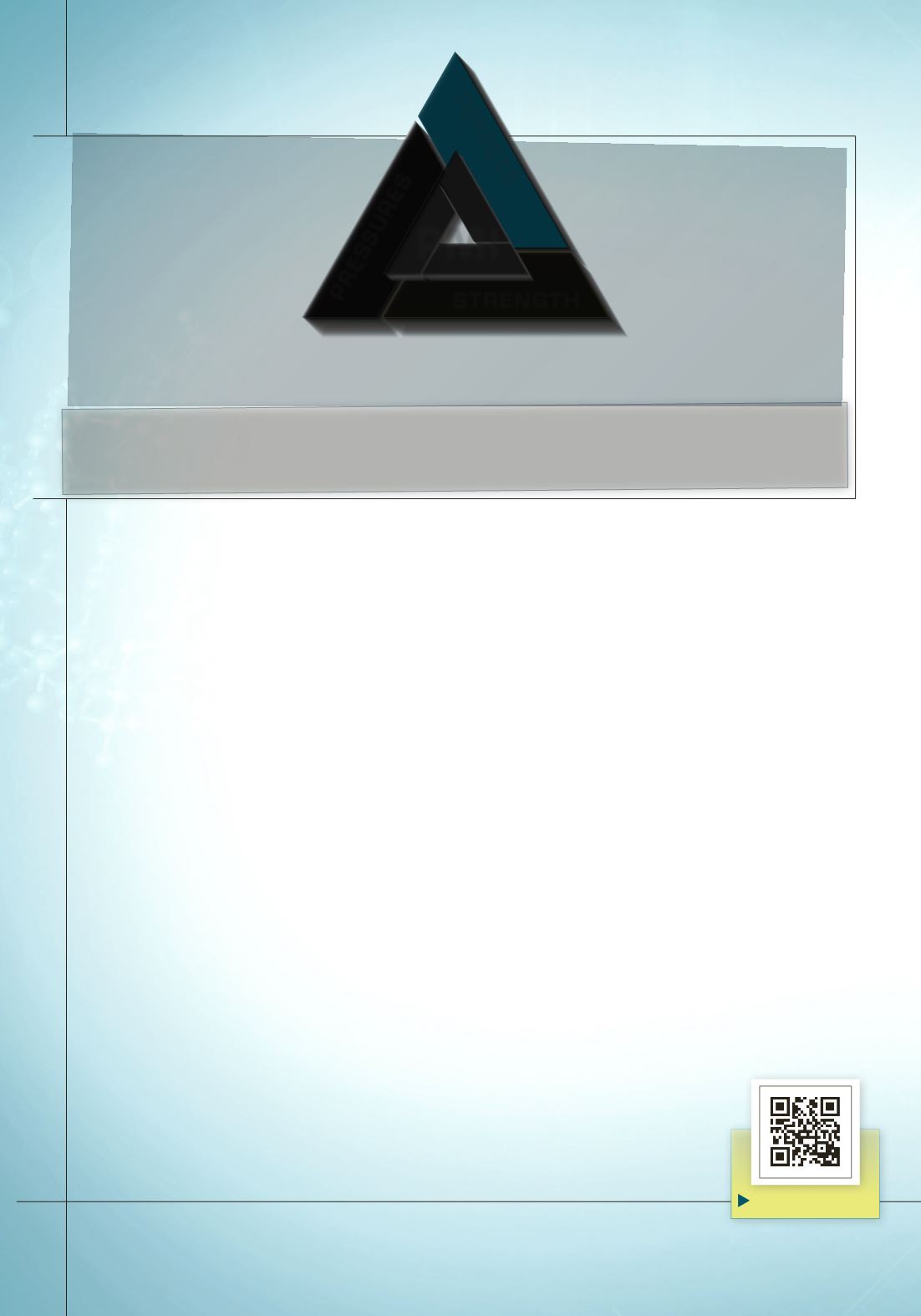

Strength

is determined by the ability to

withstand pressure

STRENGTH

PRESSURES

DEFECTS

Defects

can alter both

strength and load

Pressures

above system

limits can cause defects

to grow

There are three interdependent attributes of

positive materials identification

(PMI) technology. A lack of knowledge

about any attribute can upset the overall equilibrium.

PMI

And while the PHMSA ruling only applies

in the United States, similar benefits could

accrue for Middle Eastern and Russian natural

gas transmission and the Canadian oil sands. In

addition, verifying higher operating pressures

is considered essential for the safe operation of

pipeline reversals and conversions, two activities

that are now occurring worldwide.

NDE Techniques Can Save Time and Money

In engineering, project management, and other

disciplines, the triangle is used to represent the

interdependent nature of certain attributes, like

time, cost, and scope. The triangle is also useful

when it comes to considering positive material

identification.

In PMI, one side of the triangle represents

material strength, another is the load or pressure,

and the last side symbolizes defects. In order to

keep the triangle from collapsing, all three have to

relate to one another appropriately.

For example, strength is determined by the

ability to withstand pressure. Defects can alter both

strength and load. And pressures above system

limits can cause defects to grow.

However, a lack of knowledge about any

side can upset the overall equilibrium. With

appropriate information, operators can keep their

triangle in balance.

For generations operators have had to rely on

destructive techniques to identify pipeline materials

and MAOP, utilizing a time-consuming, costly

procedure that involved cutting out a coupon and

sending the piece away to be lab-tested.

But not any longer.

That’s because the positive material

identification process offered by global pipeline

integrity services provider T.D. Williamson

(TDW) utilizes multiple non-destructive

technologies that eliminate the need for cutting

into the pipeline and can be completed while

product continues to flow. TDW’s patent-pending

PMI can provide a high level of accuracy with less

effort, lower total cost, and shorter turnaround.

And beyond that, says Chuck Harris,

Commercialization Manager for Pipeline Integrity

Technology at TDW, the predictive nature of

TDW’s PMI techniques mean they can reduce the

potential for costly field failures when part of a

comprehensive integrity verification program.

Preliminary Results Are Nearly Instant

TDW’s PMI solution includes multiple NDE

methods (see The A-B-Cs of PMI table on the

opposite page).

The process begins by

establishing an area to inspect,

followed by determination

of yield and tensile values,

plus chemical composition

DOWNLOAD THE IVP E-BOOK