records exist, but the information is incorrect.

Soon, however, the days of missing and

incomplete materials records for gas transmission

pipeline operators in the United States will be over,

with hazardous liquids operators following shortly.

That’s because the Pipeline Hazardous Materials

Safety Administration (PHMSA) has regulation

pending that will require operators to verify the

records they use to establish and support the

maximum allowable operating pressure (MAOP) of

pipelines in high and moderate consequence areas

1

.

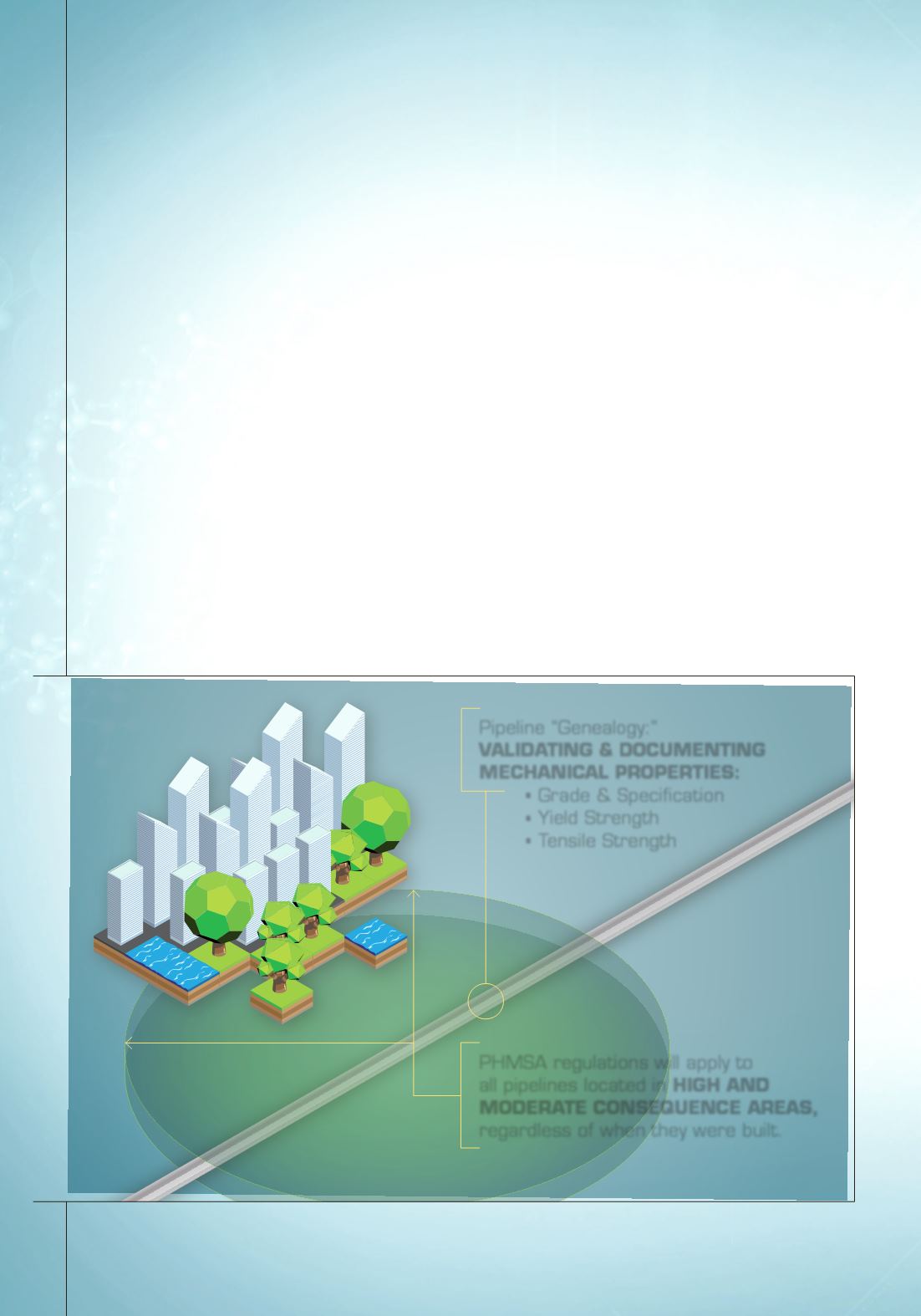

In addition, PHMSA has announced its intention to

eliminate a grandfather clause that has allowed gas

transmission operators to rely on historical data for

establishing the MAOP of pipe installed before 1970.

As a result, operators will have to perform what

is essentially a comprehensive pipeline genealogy

project in order to meet the upcoming regulations.

Included will be validating and documenting

the mechanical properties – such as construction

materials by grade and specification, yield strength,

and tensile strength – of all pipelines located in

high and moderate consequence areas, regardless of

when they were built.

But how will they find out what they don’t

already know?

Unlike curious family members, pipeline

operators can’t just search the industrial equivalent

of a genealogical database. But to get to the

information they need, there is an alternative as

unobtrusive as a DNA cheek swab: Non-destructive

positive materials identification (PMI) technology

used as part of a complete integrity verification

process (IVP).

A Call For ‘Traceable, Verifiable,

and Complete’ Records

Like any number of governmental regulations

that arose from a public safety concern, PHMSA’s

pending rules were motivated by an accident, and

a catastrophic one at that: A deadly explosion and

fire caused by the rupture of a gas pipeline in the

state of California.

In the United States, the National

Transportation Safety Board (NTSB) is among

the first on the scene to investigate the cause of

significant pipeline incidents as well as aviation,

railroad, highway, and marine disasters. During

I N N O V AT I O N S • V O L . V I I , N O. 1 • 2 0 1 5

PHMSA regulations will apply to

all pipelines located in

HIGH AND

MODERATE CONSEQUENCE AREAS,

regardless of when they were built.

Pipeline “Genealogy:”

VALIDATING & DOCUMENTING

MECHANICAL PROPERTIES:

.

Grade & Specification

.

Yield Strength

.

Tensile Strength

16

1

Visit

phmsa.dot.gov

for a criteria-based definition

of high and moderate consequence areas