a full picture of the pipeline’s condition and, in

many cases, convincing them that these lines can’t

even be inspected.

An Inspection Breakthrough For

Difficult-To-Pig Lines

T.D. Williamson (TDW) recognized the challenge

of controlling drag to improve wall thickness

inspections in a small diameter, low flow, low

pressure environment. And, in response, the

company developed a 6-inch low drag deformation

and MFL inspection tool that, according to TDW

integrity expert Lloyd Pirtle, not only “removes or

minimizes” speed excursions, but makes it possible to

inspect lines long thought of as too difficult to pig.

“This tool and capability creates confidence,”

Pirtle says. “Operators can now collect geometry

and metal loss data to know what kind of shape

their system is in – even with low flow or low

pressure – while these critical pipelines remain in

service.

“For operators with similar obstacles who’ve

thought their lines weren’t piggable, what we’re

saying is, ‘here’s a tool that can make it piggable,’”

he adds.

The new 6-inch tool not only overcomes the

design compromises that restricted navigability and

wall thickness inspection in conventional small-

diameter MFL tools, it also includes geometry

inspection on the same platform for improved

threat assessment versus stand-alone MFL.

Its advantages include:

• Greater wall thickness capability

• Reduced drag

• Improved navigability

• Improved protection of the magnetizer

Successful Field Testing

Following extensive internal validation using

multiple 6-inch tool configurations, the low drag

tool was field-tested* in partnership with Access

Midstream, a natural gas service provider and

subsidiary of energy company Williams. The tool

was run seven times on pipelines in Texas’s Barnett

Shale, at pressures around 10.34 bar (150 psi).

According to Chuck Harris, Manager, Strategic

Commercialization at TDW, although some speed

excursions occurred with the low drag tool, they

weren’t on the magnitude of those experienced

with traditional inspection tools. The tool gathered

acceptable inline inspection data at pressures as low

as 8.27 bar (120 psi).

“The technology cannot overcome line

conditions completely,” Harris says. “What’s

important is the fact that it can run in pipelines even

at such low pressures.”

In other words, the new low drag tool essentially

opens previously difficult-to-inspect pipelines to

easier, more accurate assessment.

Which can also open operators’ minds to the

possibility of pigging.

I N N O V AT I O N S • V O L . V I I , N O. 3 • 2 0 1 5

7

*Download the white paper from Access

Midstream and TDW to learn more:

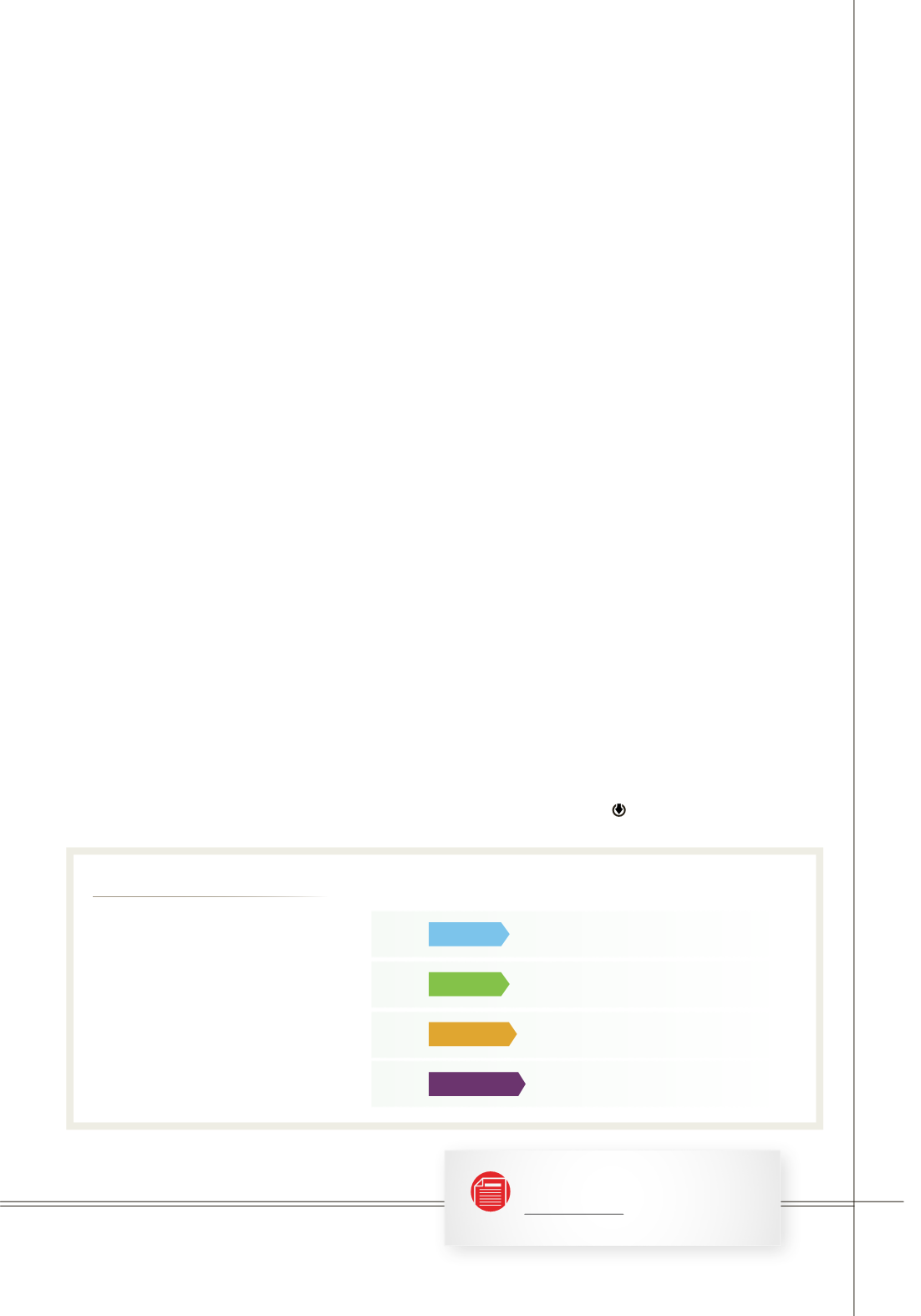

www.tdw-lflp.comDEF2+MFL4 Drag Results

Drag comparison was performed

between multiple 6-inch configurations:

MFL:

traditional stand-alone metal loss

inspection

DEF+MFL:

traditional geometry

combined with metal loss inspection

DEF2+MFL4:

newly designed geometry

combined with metal loss inspection

Drive:

drive body only

DRAG TESTING

55%

59%

61%

68%

Drag reduction vs

MFL

in

0.188-inch

Wall Thickness (WT)

Drag reduction vs

DEF+MFL

in

0.188-inch

WT

Drag reduction vs

MFL

in

0.388-inch

WT

Drag reduction vs

DEF+MFL

in

0.388-inch

WT