I N N O V AT I O N S • V O L . V I I , N O. 3 • 2 0 1 5

6

T E C H N O L O G Y F O C U S

Every day, there’s another example of technology making

the impossible possible.

But making the difficult-to-pig easier-to-inspect?

That’s an entirely new triumph.

For natural gas operators, inspecting geometry and wall-loss in

small diameter gathering lines, especially in low flow, low pressure

environments, has been a challenge. So much so, in fact, that many

operators have their minds made up: it just can’t be done.

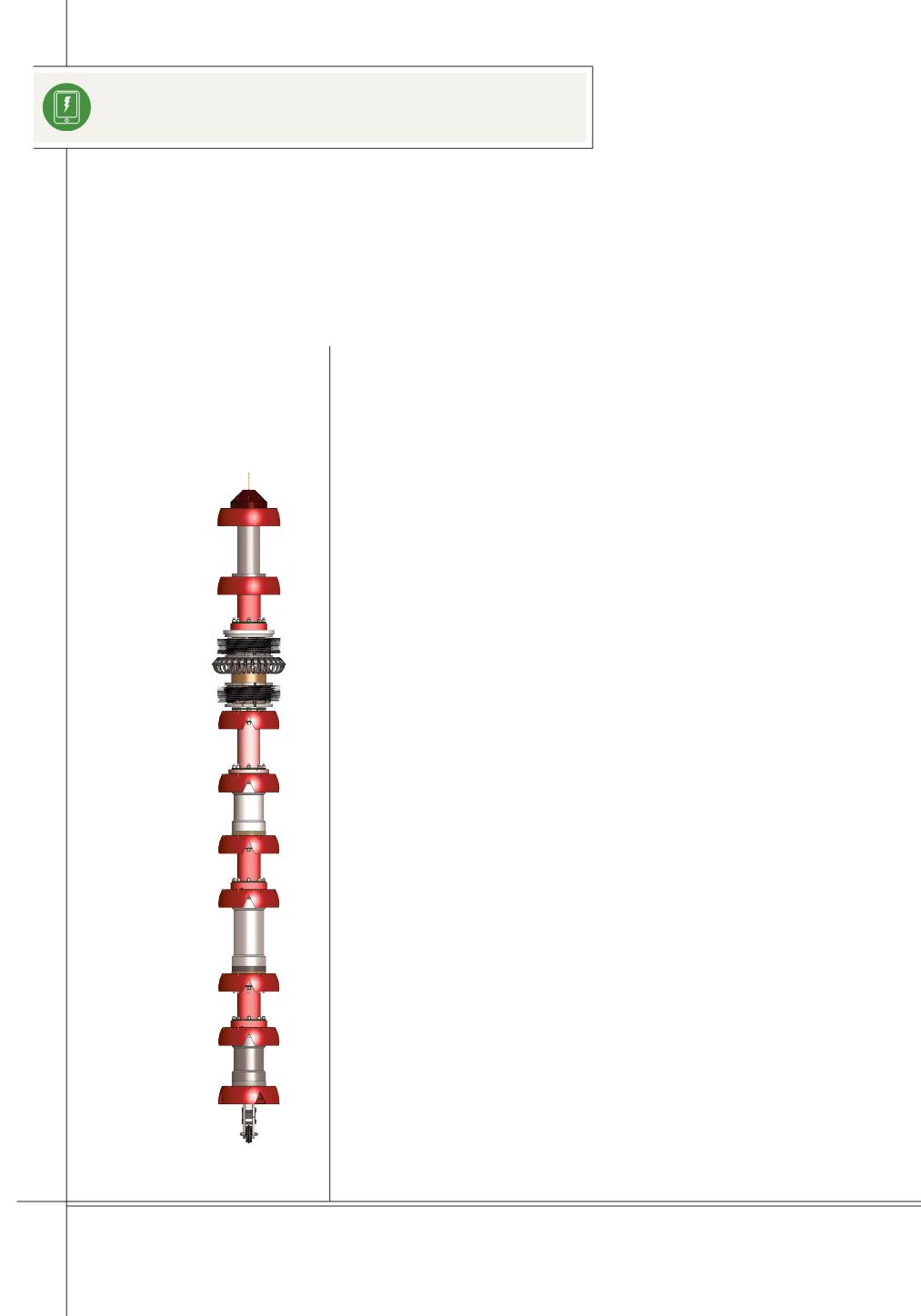

Now, however, there’s a new 6-inch inspection tool that overcomes

problems of size, flow, and pressure in these difficult pipelines.

Not only does it gather data for integrity assessments, it might just

change how operators view the possibility of pigging.

Avoiding Turbulence

An inline tool moves when pressure differentials around it are greater

than the friction produced by the tool itself. In the case of inspection

tools used to survey geometry and measure metal loss, progress through

pipelines is generally slow and steady. Accurate data is captured at

regular points along the line, creating a successful integrity assessment.

But during the inspection of small diameter, low flow, low pressure

pipelines, certain magnetic flux leakage (MFL) tool components – such

as urethane cups and brushes – make contact with the pipe’s interior.

This can create significant drag, which is additional frictional pressure

within the line. And drag can make an inline inspection (ILI) tool’s ride

turbulent, impairing its performance in compressible products such as

natural gas.

For one thing, drag can cause speed excursions, where the tool

accelerates abruptly and lurches ahead before returning to its normal

pace. Unless it stops completely. A standstill could last 10 seconds or

10 hours – sometimes even longer – and might eventually require an

intrusive intervention like having to cut out the MFL tool or launch a

foam pig from behind to push it along.

Drag-related speed excursions, which can be greatly exaggerated in

low pressure and low flow natural gas pipelines, prevent the ILI tool

from capturing data at every point – keeping operators from getting

Turning

Impossible

into Piggable

New 6-inch, low drag

inspection tool changes

how operators think about

assessing low flow, low

pressure lines