1

I N N O V AT I O N S • V O L . V I I I , N O. 1 • 2 0 1 6

2 |

EXECUTIVE OUTLOOK

Culture: Your

Competitive Edge

4 |

GLOBAL PERSPECTIVE

Industry Commentary

From Around The World

6 |

TECHNOLOGY FOCUS

Prioritizing Selective Seam

Weld Corrosion

8 |

SAFETY MATTERS

Reducing Risk by Reducing

Exposure

10 |

FUTURE THINKING

Addressing the NDE

Technician Shortage

12 |

MARKET REPORT

Preserving Knowledge;

Preparing for the Future

20 |

TOUCHPOINTS

Pipeline Events, Papers,

and Conferences

28

|

BY THE NUMBERS

The Three Steps of Pipe

Identification

14 |

Safe Passage

With more North American crude being moved to market from

the Bakken and Canadian oil sands, pipeline and rail operators

share responsibility for improving energy safety.

22 |

A Global Race Against Time

The world’s gathering lines are aging. What can the industry do

to share information, reduce risks, and eliminate incidents?

D E P A R T M E N T S

EDITOR-IN-CHIEF

Jim Myers Morgan

MANAGING EDITOR

Waylon Summers

ART DIRECTOR

Kat Eaton

DESIGN PRODUCTION

Mullerhaus.net, Kat Eaton

DIGITAL PRODUCTION

Jim Greenway, Ward Mankin

ILLUSTRATION

David Moore

PHOTOGRAPHY

Ezequiel Scagnetti

T.D. Williamson, Inc.

North and South America +1 918 447 5000

Europe/Africa/Middle East +32 67 28 3611

Asia Pacific +65 6364 8520

Offshore Services +47 5144 3240

www.tdwilliamson.comWant to share your perspective on anything in our magazine?

Send us an e-mail:

Innovations@tdwilliamson.comV O L . V I I I , N O. 1 • 2 0 1 6

Innovations

™

Magazine

is a quarterly publication produced by T.D. Williamson, Inc.

®Registered trademark of T.D. Williamson, Inc. in the United States and other countries. ™ Trademark of T.D. Williamson, Inc. in the United States and other countries.

© T.D. Williamson, Inc. 2016 Reproduction in whole or in part without permission is prohibited. Printed in the United States of America.

14

10

22

28

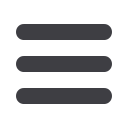

Phases

Four

BYTHE

NUMBERS

of

PROGRESSIVEPIGGING

29

Three

UsePipe JointClassification (PJC)

– based on pipematerial

characteristics gathered through comprehensive inline inspection tools,

such as theMultipleDataset (MDS) platform – to group each pipe joint

into like-bins based on attributes including,but not limited to:

PIPELINES SHOULDHAVE TRACEABLE,VERIFIABLE,AND

COMPLETERECORDS,

includingmaterial documentation to

supportmaximum allowable operating pressure (MAOP) validation.

Butwhat about pipeline segments that are decades old?Or assets

thatwere oncemanaged by one operator,sold to another,and then,

potentially,sold again?

The answer?Pipe Identification (PI).

Correlateexisting pipe records,

if any, to thePJC bins.

If all records align to a characterized

pipe bin, Pipe Identification has

been achieved.

If records gaps persist,

proceed to step3.

EmployPositiveMaterial

Identification (PMI)

– an in-situ non-destructive evaluation

methodology – to identifymaterial

propertieswhere records do not exist for

a given pipe joint or PJC bin.With all pipe

joints aligned to the appropriate bin,and

remaining gaps closed through PMI,

Pipe

Identification has been achieved.

•Materialmagnetic characteristics –

impacts from both themanufacturing

andmilling process.

• Pipe type –

seamless or seamed.

• Seam characteristics –

differentiate

seams formed through diverse

welding processes.

Traceable.

Verifable.

Complete.

PJC

+PMI

———

PI

Step

ipe Identification

1

2

3

Learnmore by dowloading the Pipe

Identificationwhite paper:

www.tdw-PipeID.com