8

Reducing Risk by

Reducing Exposure

Ask any decision-maker in the pipeline industry about their

company goals, and you’ll probably get an answer along these lines:

“Maximize throughput and efficiency as much as possible while

protecting both our personnel and the environment.”

Meeting that goal requires a cost/benefit analysis that oil

and gas companies face every day, even during relatively simple

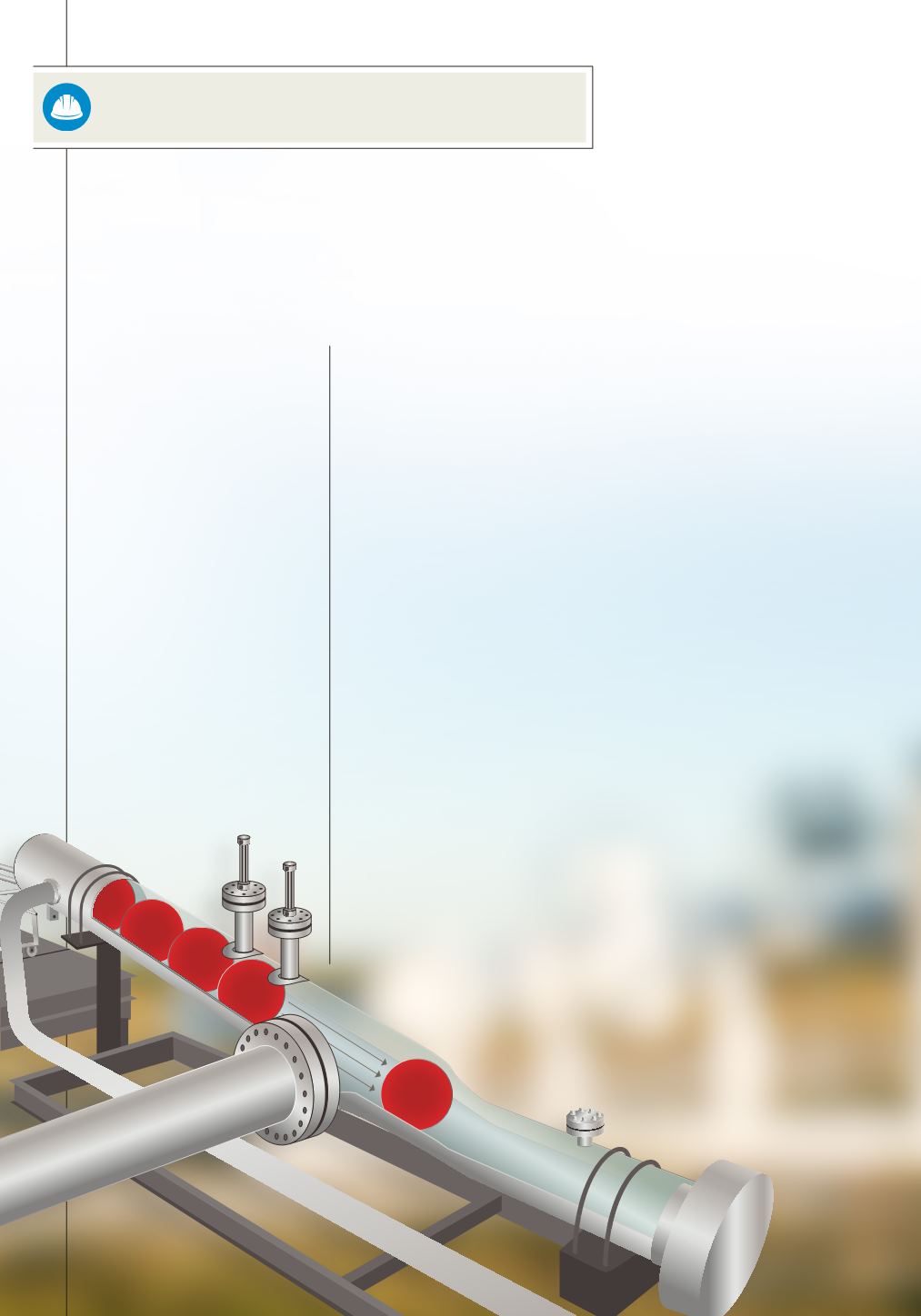

maintenance procedures. Pigging, for example, is a process necessary

for maintaining pipeline integrity. It cleans the inside of the line

– removing wax, debris, and water – helping to ensure an efficient

pipeline. But pigging also involves a lot of human interaction with

the pipeline, which always carries a certain level of risk.

Automated pigging systems allow multiple pigs to be loaded at

once and launched at predetermined intervals. Automation reduces

human contact with the pipeline by up to 85 percent over non-

automated pigging, which requires opening the pipeline each time a

pig is launched. Automating this procedure lowers the level of risk to

both employees and the environment.

Reducing Risks

Pigs are heavy – ranging from just a few pounds to several hundred.

Even with safety procedures in place, human error while handling

pigs can cause accidents. “I spoke to one customer who had a

technician on sick leave for over a year,” says Abdel M. Zellou, a

market development director for T.D. Williamson. “He had a back

injury related to loading and unloading pigs.”

Accidents don’t just happen at the maintenance site – they

happen on the road, too. Automation cuts down on potential

indirect injuries by reducing the time spent traveling over bumpy

roads to remote locations.

S A F E T Y M AT T E R S

I N N OVAT I O N S • V O L . V I I I , N O. 1 • 2 0 1 6

Automation as a Benefit

to Health, Safety, and

the Environment