Not only does driving increase the risk of

accidents, but driving for hours is also a waste of a

skilled technician’s time. Because certain automation

systems allow technicians to load up to seven pigs in

one trip, it means that they can spend less time on

the road.

Aiding the Emission Mission

A natural gas pipeline system is like a pressure

cooker: To open the trap and insert a pig, you

need to depressurize it first by letting out the

methane gas inside it. Methane is a greenhouse

gas regulated by the United States Environmental

Protection Agency (EPA), and according to the

EPA, natural gas and petroleum systems are the

largest industry sources of methane emissions.

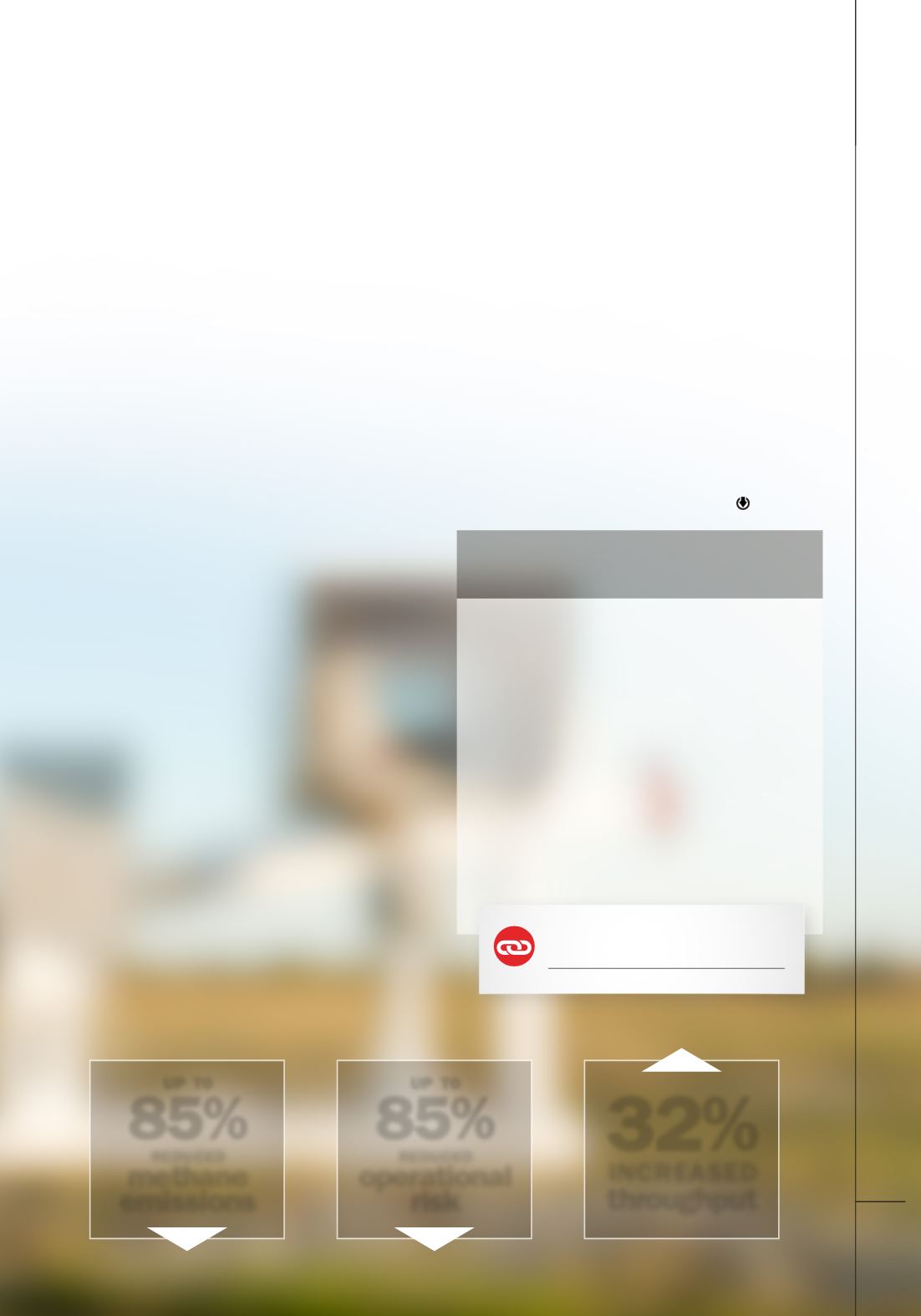

Automated pigging means that technicians

only have to allow methane into the atmosphere

one time per seven pigs, instead of each time they

launch a pig. Like the risk to injury, automating

this practice reduces emissions from pigging by up

to 85 percent.

Controlling emissions helps pipeline

companies comply with industry regulations

such as the Methane Challenge, an initiative

proposed by the EPA in July 2015 in response

to the Obama administration’s goal to reduce

methane emissions from the oil and gas sector.

The Methane Challenge is part of the Natural Gas

STAR program, and is a voluntary way for oil

and gas companies to make general commitments

toward methane emission reduction, track their

progress, and receive recognition.

“One of the primary goals of the program is to

provide guidance in identifying and prioritizing

cost-effective ways to reduce emissions from oil

and natural gas operations,” as stated on the

EPA website. “There has been a good amount of

engagement and interest.”

To help companies lower emissions, the EPA

identifies certain procedures that require venting

gas. One such category is liquid unloading actions

during which gas is vented. Pigging falls into that

category.

Several companies have already signed up for

the program, including Hess, Kinder Morgan, and

Apache. One major benefit to these participants

is they will be recognized as leaders in reducing

emissions in the United States.

And the program benefits the industry as a

whole: By automating some procedures in order

to reduce methane emissions, pipeline companies

are also reducing risk to their employees. For

many companies, these factors will swing the cost/

benefit analysis in automation’s favor.

I N N O V AT I O N S • V O L . V I I I , N O. 1 • 2 0 1 6

9

Other Sources of Methane Emissions

Actions that require venting gas, like pigging, are

one way that the energy industry emits methane

into the atmosphere. The U.S. EPA has identified

other sources of methane emissions as well, such as

pneumatic controllers, equipment leaks, pneumatic

pumps, hydrocarbon storage tanks, reciprocating

compressors-venting, and centrifugal compressors-

venting.

The Methane Challenge program suggests

different ways to work with these sources to reduce

emissions. One example is using low- or no-gas bleed

pneumatic controllers, except in circumstances that

demand high-bleed controllers for safety reasons.

Find out more about the program on the Methane Challenge website: www3.epa.gov/gasstar/methanechallengeup

to

85%

reduced

methane

emissions

up

to

85%

reduced

operational

risk

32%

increased

throughput