based, and students can apply what they’ve learned

to a broad range of industries, from structural

steel to pipelines. After completing the requisite

classroom hours, students complete 1,000+ hours

of supervised, industry-specific fieldwork, unique

to their area of NDE focus.

So far, there’s no single, permanent way to

create a pool of trained, qualified NDE technicians,

but there have been some promising developments.

Many colleges and technical schools currently offer

two-year programs focused on NDE training. In

addition, the industry has started to reach out to

college graduates with new certification programs

that reduce the training hours required for trainees

with four-year degrees in engineering or science.

Pipeline service companies are also finding

creative ways to build a larger pool of available

NDE technicians: Some are pulling technicians

from other departments or even other industries.

Because there is a common knowledge base for

non-destructive technology (NDT), a technician

with years of experience in aerospace, for example,

can transition to pipelines.

What’s more, many NDE companies –

companies that haven’t previously worked with

pipelines – have started to expand their service

offerings beyond structural steel or refineries to

include pipeline integrity.

Others in the industry are creating entirely

new solutions. Kenny Greene, a Level 3 NDE

technician in Arizona, recently started a pipeline-

specific training program that helps students

earn field hours in internship-like arrangements

with partner companies. The program, called

“WAR2IN” (“Warrior to Inspector”) is aimed at

former military personnel. If successful, this type of

specialized training may become more common.

The industry is still adapting to the growing

demand for NDE technicians. It’s a challenge, to

be sure – but one thing is clear: There’s no shortage

of creative ideas that will help draw qualified,

talented technicians to the field and help operators

ensure that their pipelines are operating safely and

effectively.

11

I N N O V AT I O N S • V O L . V I I I , N O. 1 • 2 0 1 6

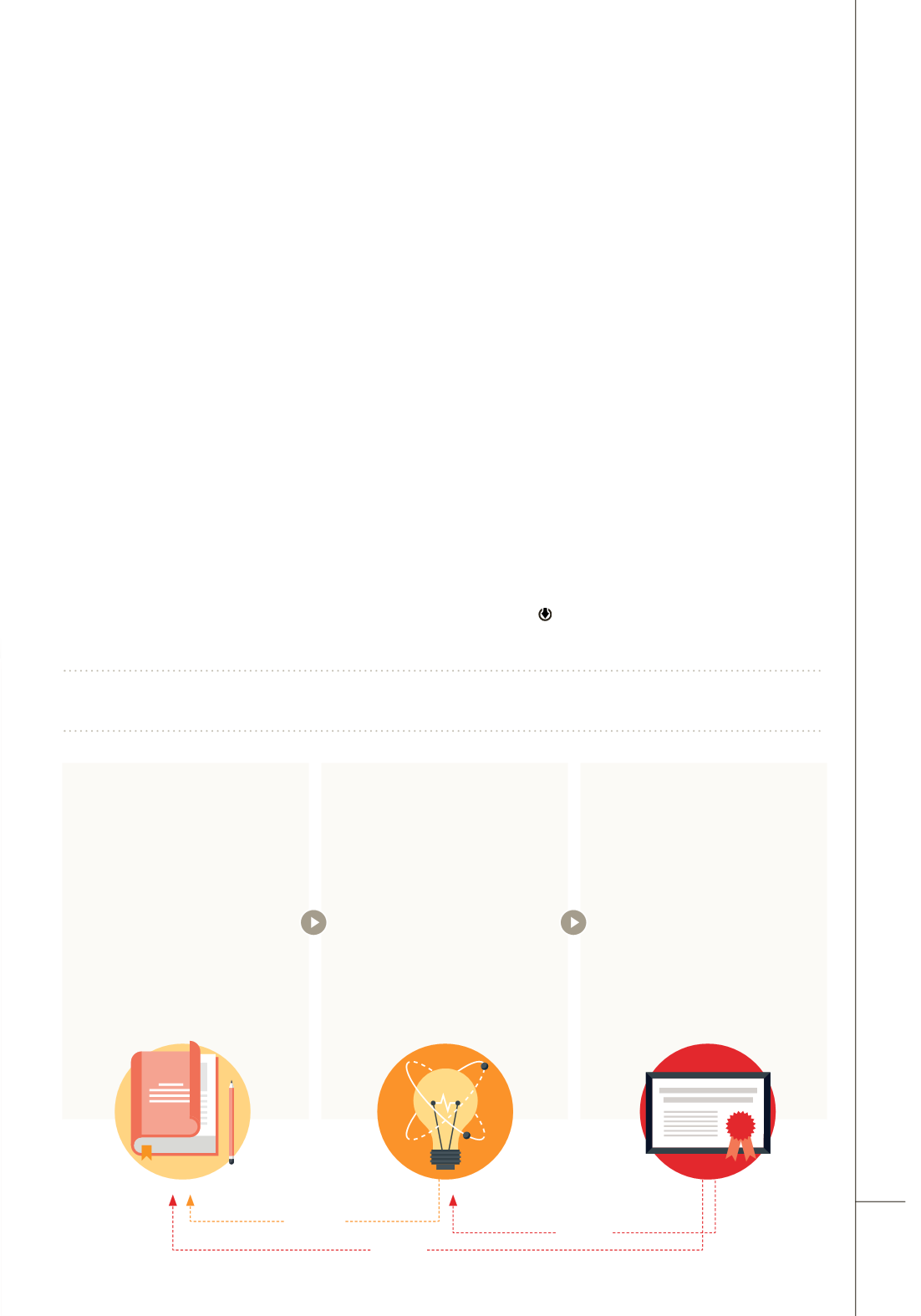

LEVEL

1

T E C H N I C I A N S

have typically completed all

required classroom training and are

gaining field experience by filling

apprentice-like roles under the

guidance of a Level 2 supervisor.

A Level 1 technician can collect

data, but cannot interpret or report

that data.

LEVEL

2

T E C H N I C I A N S

have completed all classroom/formal

training and all supervised field

training. Technicians at this level can

collect, interpret, and report on NDE

data. They also serve as mentors and

supervisors to Level 1 technicians

completing field hours.

EXPERT PROGRESSION

LEVEL

3

T E C H N I C I A N S

are typically responsible for certifying

Level 1 and 2 technicians within their

companies. Technicians at this level

hold certification through an outside

organization. In the United States,

for example, Level 3 technicians are

certified by the American Society for

Nondestructive Testing (ASNT).

CERTIFY

CERTIFY

MENTOR