Ameen. “That way we were able to get it all to

Singapore to do a final assessment test before

going offshore.”

“Such complex operations typically take

several months to plan,” explains Ang.

ALL HANDS ON DECK

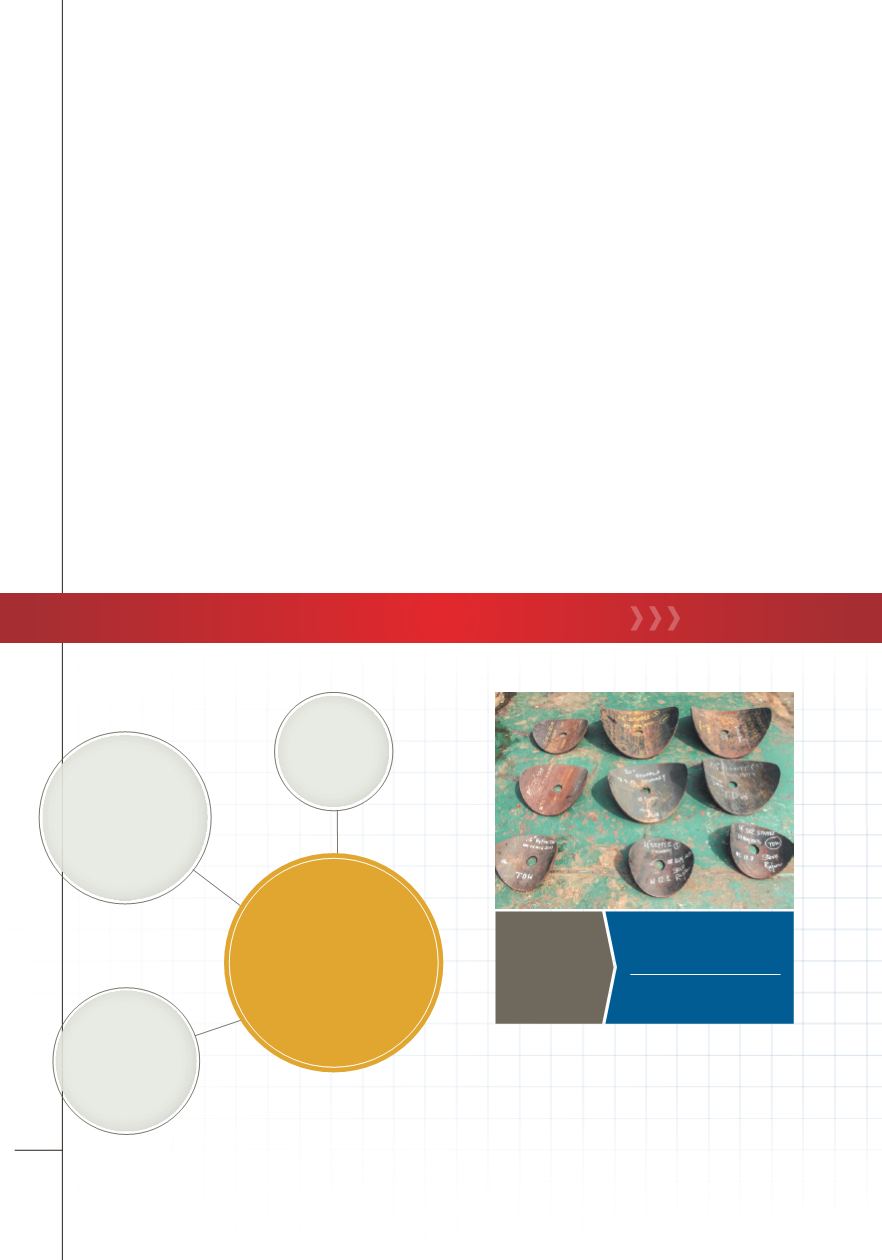

TDW, Pertamina EP and the contractors all met

to plan every detail of execution. First, various

pieces of hot tap and plugging equipment from

North America, Europe, and Asia Pacific were

gathered in Singapore, along with a team of

expert technicians. Once they completed system

integration testing and a mock-up simulation

of 14-, 20- and 24-inch hot tap and STOPPLE

plugging, the team was ready to mobilize to the

offshore jobsite.

In hot tapping and plugging, the entire

execution is performed by subsea divers. The

underwater operation takes a great deal of skill

to avoid human error. For example, if the plug

setting is not completed, the pipe contents can

escape, causing a potential safety hazard and

wasting valuable product.

A diving contractor was brought on to

support the project with their divers and dive

support vessels (DSVs). Working in five-

member teams at depths of 131 feet below the

surface, the divers deployed a 1200 XL and a

SubSea 1000 XL Hydraulic Operated Tapping

machine. They took field measurements on

the subsea mechanical clamps to calculate the

cutting distance, then mounted the tapping

equipment and completed the hot taps to cut

into the pipeline.

SAVING TIME WITH

SIMULTANEOUS ISOLATIONS

With all nine hot taps completed, it was time

to carry out the task of installing six STOPPLE

“

SUCH COMPLEX OPERATIONS TYPICALLY

TAKE

SEVERAL MONTHS

TO PLAN

”

– EDMUND ANG

TESTING &

MOCK-UP

SIMULATION

FOR HOT TAP

& ISOLATION

24

in.

PIPE

DIAMETER

14

in.

PIPE

DIAMETER

20

in.

PIPE

DIAMETER

MAKING THE IMPOSSIBLE

POSSIBLE

I N N O V AT I O N S • A P R I L - J U N E 2 0 1 4

18

63

DAYS

EXECUTED

SIMULTANEOUSLY

9

HOT TAPS

6

ISOLATIONS