27

I N N O V AT I O N S • A P R I L - J U N E 2 0 1 4

Raising Lima

CONTINUED FROM PAGE 19

INCREASED SAFETY

»

»

No potential leak path

through flange

»

»

No plug drop

»

»

Interlock system

»

»

Operator can retrieve set,

pressurized plug without being

positioned over it

EFFICIENCY

»

»

Easier, quicker setting process

»

»

Plug can only be set correctly

»

»

Correct coupon alignment

eliminates piggability problems

MAINTENANCE

»

»

Flange and plug have fewer

parts compared to standard

LOCK-O-RING design

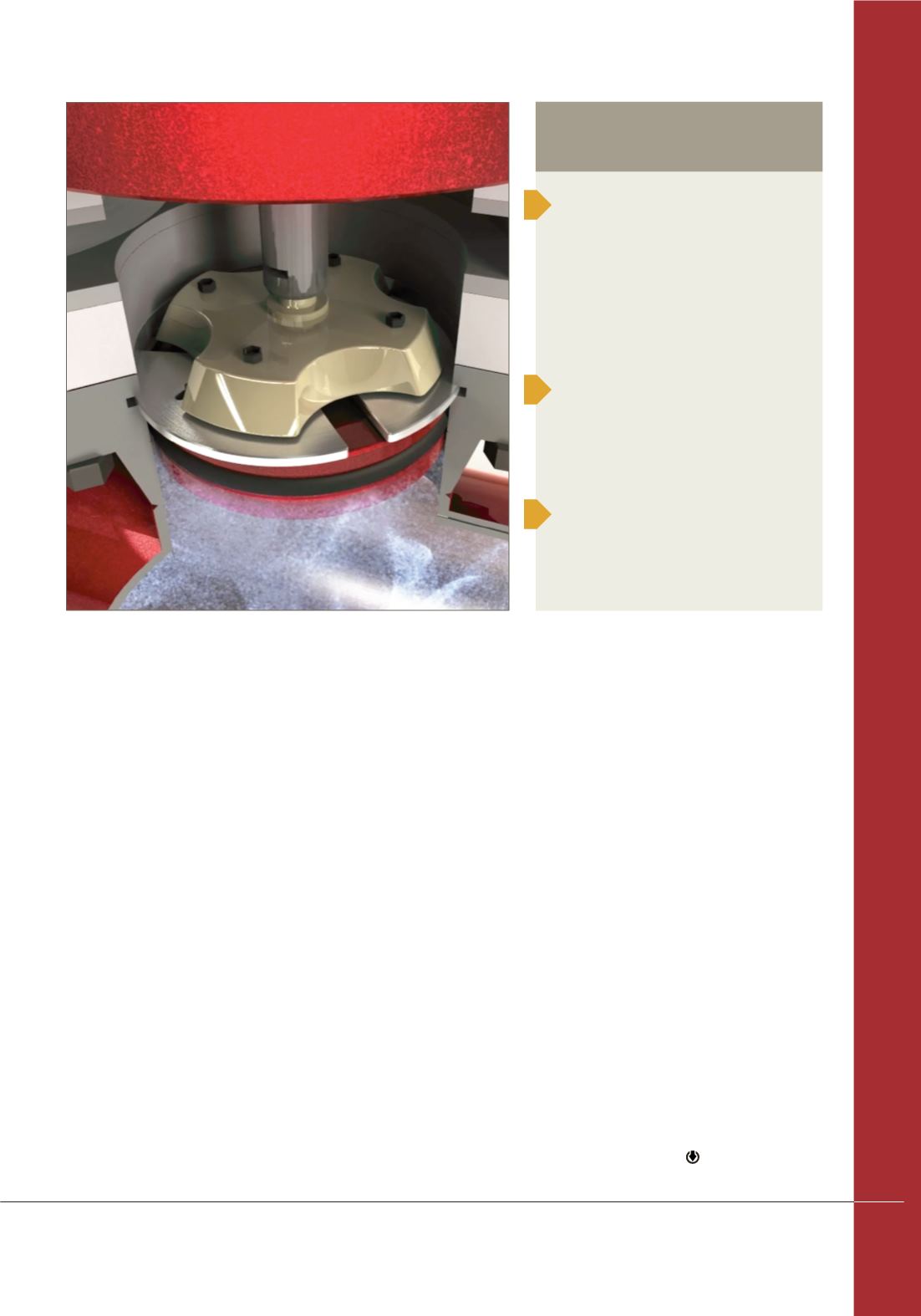

SIMPLICITY EQUALS SAFETY

Once the leaves are fully extended, the LOCK-O-RING

®

Plus

completion plug provides operators increased safety and simplicity.

LOCK-O-RING

®

Plus Plug

Features & Benefits

plug has been set. With divers struggling with

traditional, unwieldy equipment, each plug

setting can take several hours.

To save time, the team decided to try something

previously performed only onshore: Installation of

LOCK-O-RING® Plus completion plugs.

This completion plug technology was patented

in early 2011, and has been successfully used to

complete multiple onshore STOPPLE isolation

jobs. The technology had been thoroughly

tested for subsea, but had not yet been used

on a subsea job.

Each STOPPLE fitting has a flange with no

side openings, which reduces any potential leak

paths. This flange helps with the attachment of

the bypass system. Once the bypass is removed,

the flange can also assist with the attachment of

the LOCK-O-RING Plus completion plug.

A feature of the completion plug that made it

the right tool for Pertamina EP’s project is that

its interlock system indicates when the leaves

are fully extended, which lets divers know, with

certainty, when it is positively set in the flange.

Plus, the plug setting machine used to set the

plug transfers pressure from the pipeline to the

inside of the plug setter, balancing the pressure

by counteracting the force pushing against the

machine. Altogether, this system provided divers

and engineers with a quicker and safer way to

complete their work underwater.

PERTAMINA EP’S CUSTOMERS

CONTINUE TO COOK

The Lima project was a distinguished introduction

of the LOCK-O-RING Plus completion plug to its

new subsea application. Now that the technology

has proven to be effective underwater, the door has

been opened to using the technology in similar

projects following the shared experiences and

lessons learned by Pertamina EP, the contractors

and TDW’s project managers.

Most importantly, Pertamina EP was able to

raise their Lima Flow Station without any incidents

or disruptions to the gas supply. Jakarta and the rest

of West Java had gas for cooking and power, and

Pertamina EP didn’t lose profits from a shutdown.

“We asked our team to make the impossible possible,

and they did it,” says Nababan.

C O V E R S T O R Y