9

I N N O V AT I O N S • A P R I L - J U N E 2 0 1 4

SmartPlug technology, was involved in planning

meetings from the start. For the project, they

worked through various scenarios and emergencies:

How will communication work? How will the

diving control center on the vessel get information

on the status of the isolation? What’s considered

a sound isolation, and what should be done if

something does not meet the criteria?

The collaborative planning proved to be worth it.

After the technicians deployed and activated the

SmartPlug tools on each side of the target area, one

of the seals wasn’t keeping the pressure consistent

enough. While the pressure was in normal range, it

did not seal to the operator’s unique requirements.

These project-specific limits were specifically

designed to provide additional diver safety during

the operation.

Now, the teams had the ability to follow the

established contingency plan. They quickly pulled

the plug and replaced it with a backup plug at

another location in the pipeline, which worked.

Due to the pre-planning, the teams didn’t need to

stop and develop a response to the setback.

A New Mode of Operation

Some service companies are taking their

involvement in risk assessment and planning one

step farther. For example, at TDW, technicians

receive specific training aimed at getting them to

see things from the operator’s perspective. In the

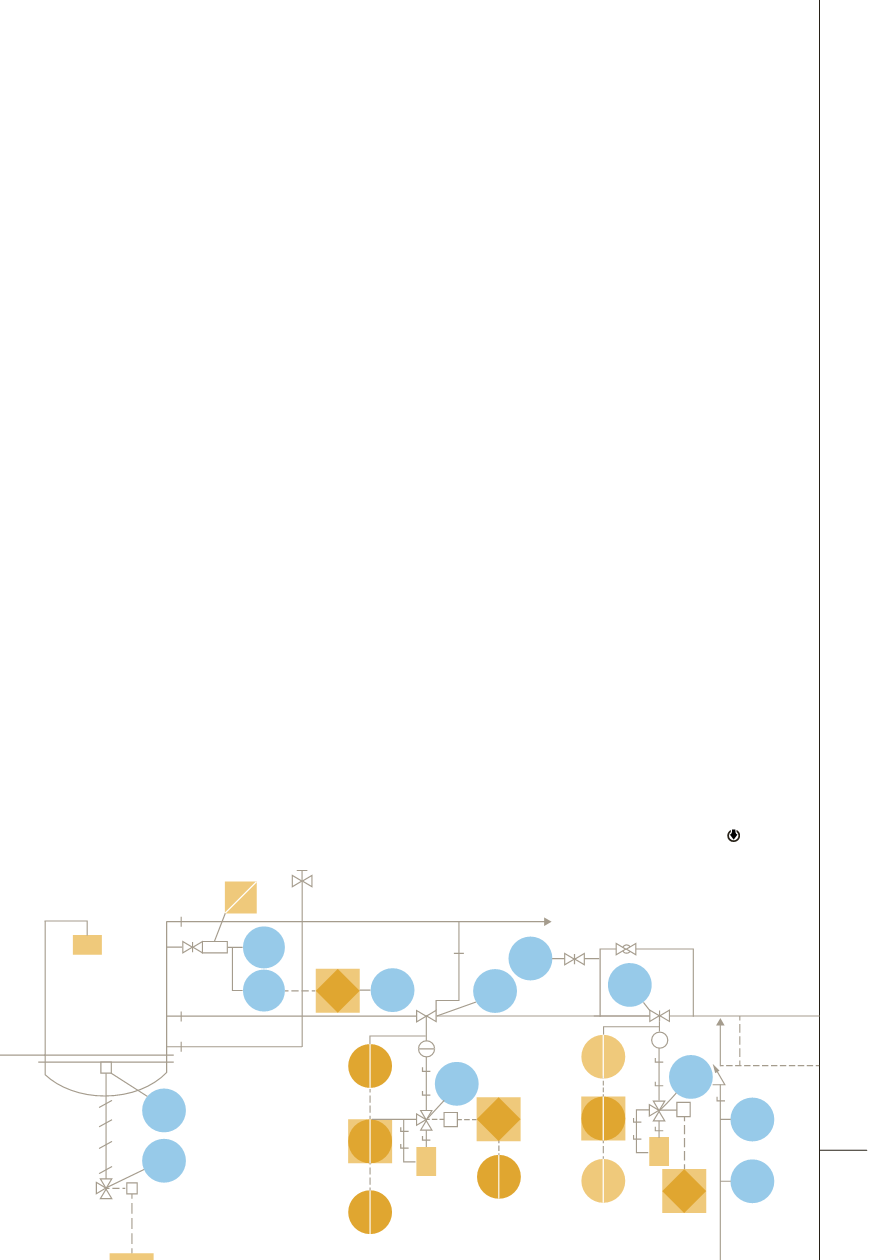

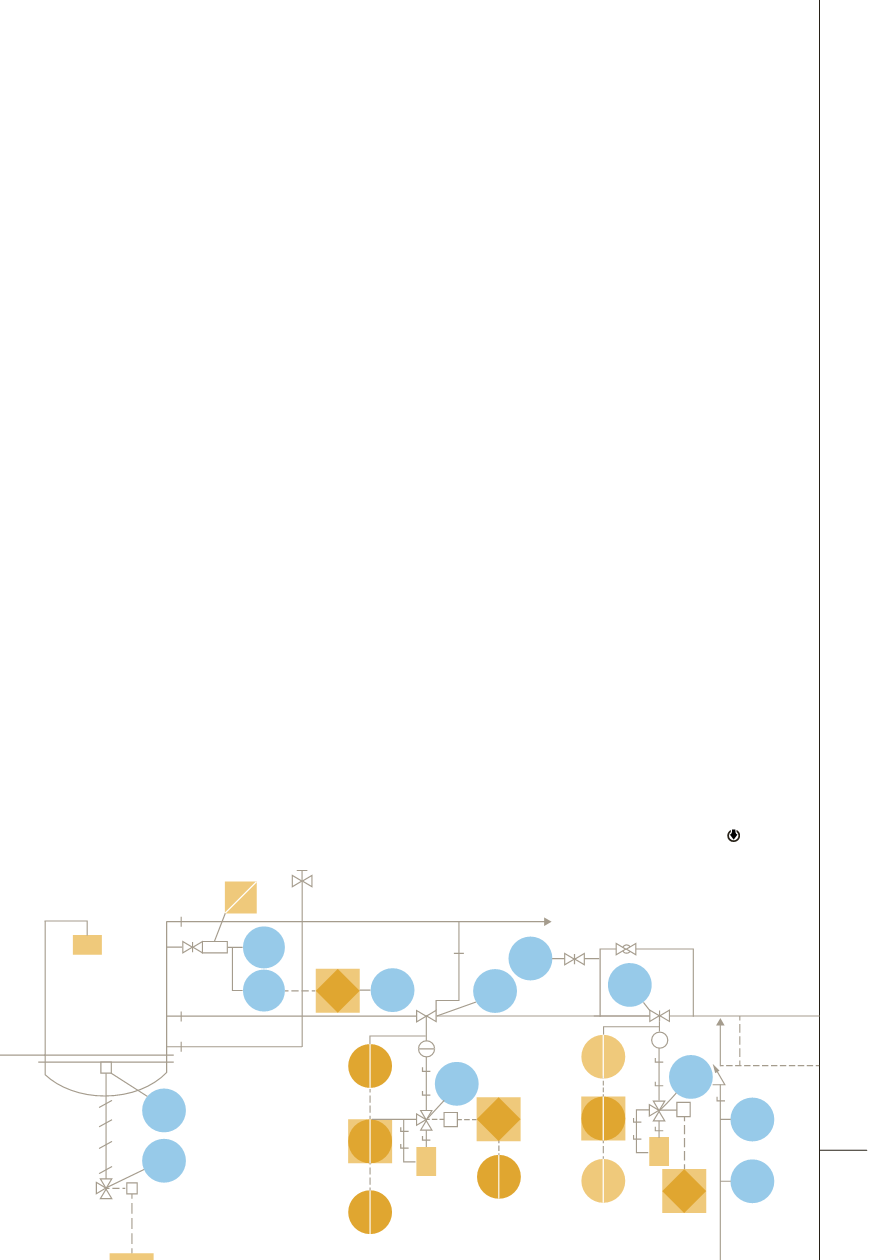

training, engineers teach technicians how to read the

P&ID (called either a Piping and Instrumentation

Diagram or a Process and Instrumentation Diagram,

depending on the company) and to analyze and

understand the full environment surrounding

the isolation operation, not just in relation to the

particular tool.

By thinking beyond how the tool operates, to

how it impacts and is impacted by what’s happening

on the platform or facility where the isolation is

taking place, the technicians are better prepared to

consult operators in the project planning phases.

Larry Ryan, Director of SmartPlug Operations

for TDW, says this new way of doing business isn’t

always easy, but it’s certainly worth it. “The P&ID

diagrams are highly technical, so learning how to

read them is like learning a different language. But

with this added knowledge, our technicians can sit

in the HAZOPs and discuss what would happen

if things don’t go exactly as planned. They can’t

do that unless they can understand the diagrams.

Without that understanding, we can’t effectively

engage in high-level risk discussions. We’d be too

tool-centric and not environment-centric.”

Cool-headed Decisions

When service company personnel and operator

staff share knowledge from day one, the team as

a whole is better equipped to handle situations

that arise and keep a cool head when things don’t

go correctly.

“When you’re offshore, and you’ve got your

whole field shut down on a huge pipeline and

infrastructure, time is not your friend,” Ryan said.

“So the last thing you want to do is make decisions

in the heat of the moment. You want to make them

in the cold light of day when everyone is sitting

around onshore, before anything happens.”