I N N O V AT I O N S • A P R I L - J U N E 2 0 1 4

4

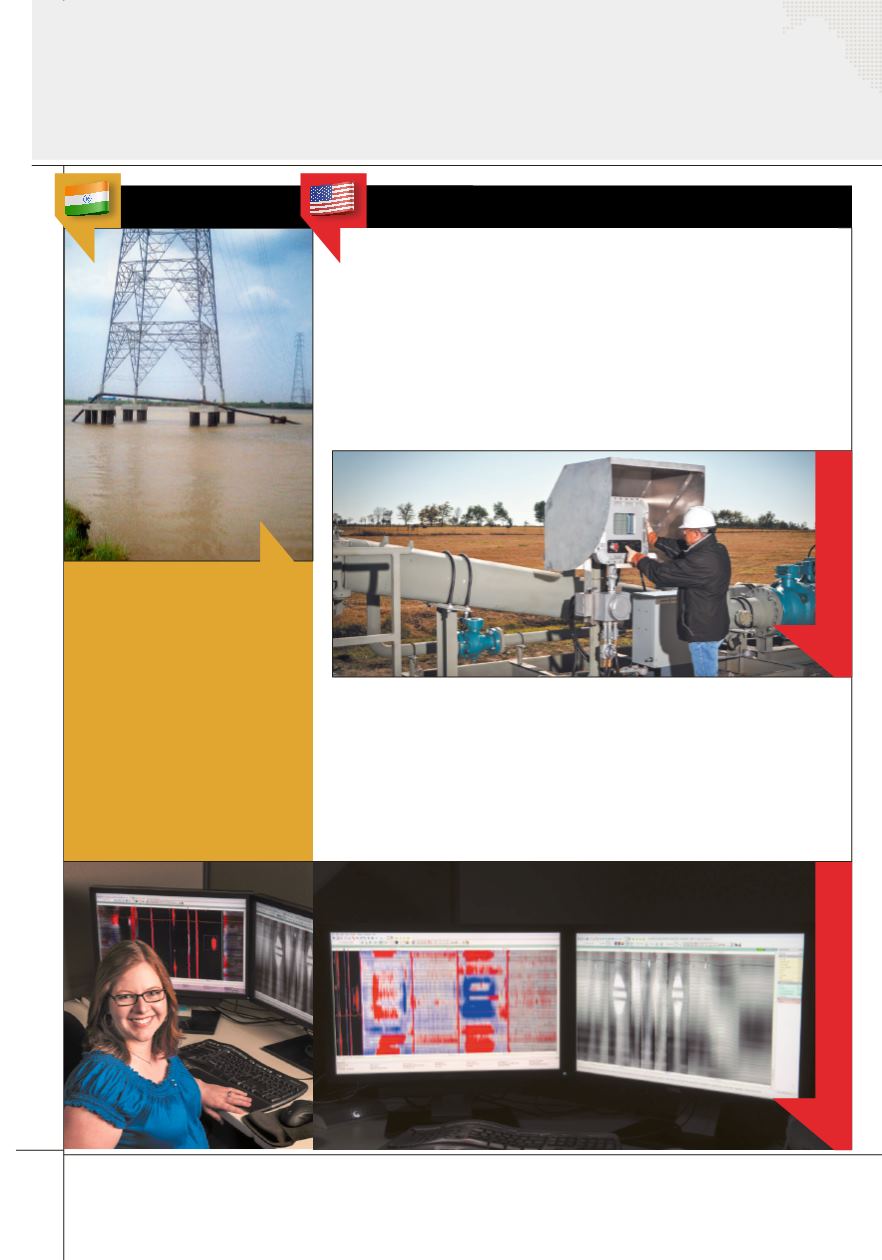

Automation is Key

To increase the efficient control of both the volume and flow of natural gas

liquids into its processing plant, a provider in Ohio invested in its second 24” x

30” SmartTrap® Automated Combo Pigging System, replete with accompanying

infield service. In addition to significantly reducing the manpower requirements

associated with the daily pigging of its 24” trunk line, the automated launcher

will lessen wear and tear on its 24” valves, minimize employee exposure to

hazardous environments, and reduce the escape of “unaccounted for natural

gas” from closure openings.

Increase in Eagle Ford

One of the top 10 producers in the Eagle Ford shale play has recently maximized

the throughput of its extensive small diameter gathering system by adopting

a progressive pigging and integrity management program provided by TDW.

Following thorough cleaning of its 6", 8", 10" and 12" lines with progressively

more aggressive pigs, the operator is now reaping the benefits of maximized flow

and more acccurate data from its DEF and MFL integrity inspection runs.

INDIA

USA

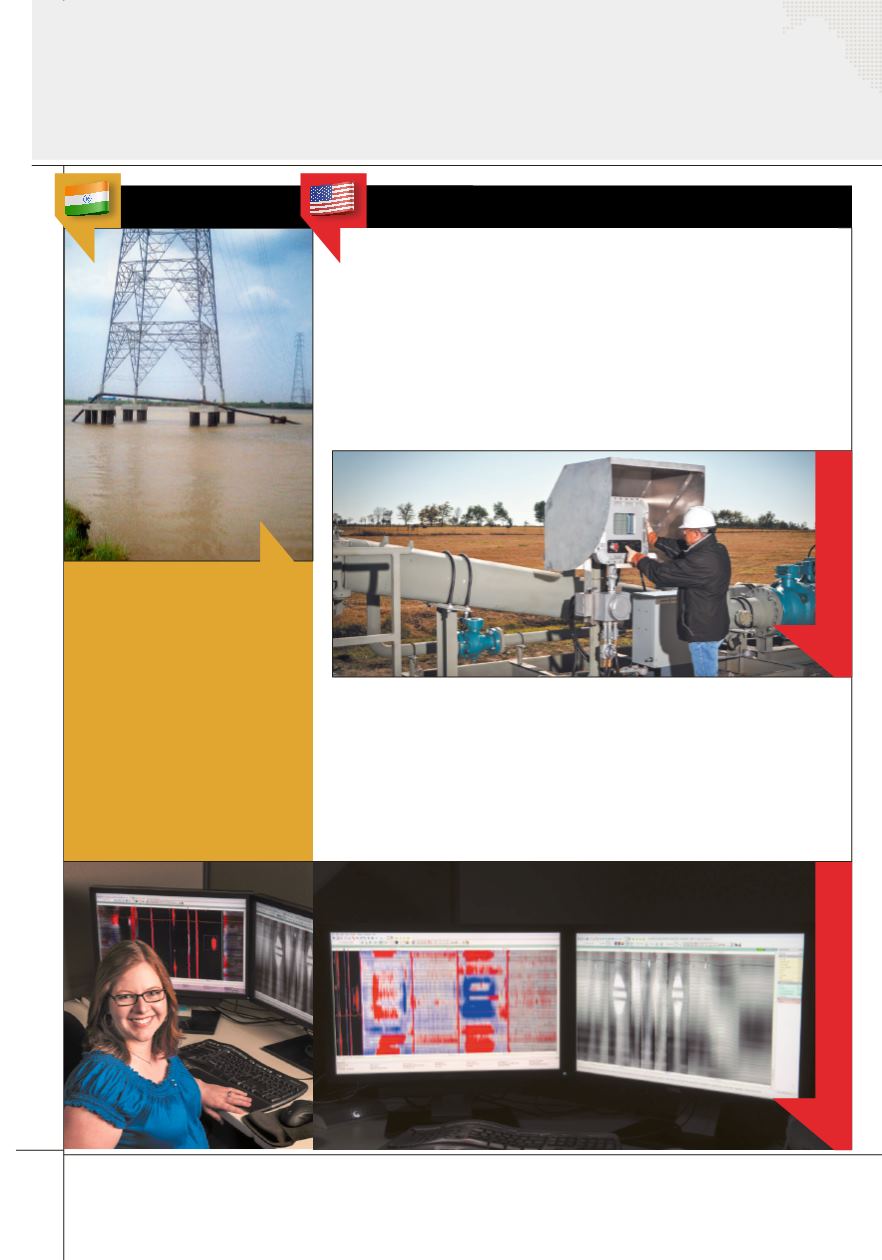

Forces of Nature

A submerged 30" gas pipeline

ruptured due to strong floodwater

currents following heavy rains and

was forced through 5 to 8 meters

of river bottom, shooting nearly 30

meters above the water level. The

operator was forced to shut down

the line. However, TDW was able to

mitigate the loss by quickly creating

a bypass to allow product to flow

within just 5 weeks.

Global

Perspective