28

Phases

Four

BY THE

NUMBERS

Three

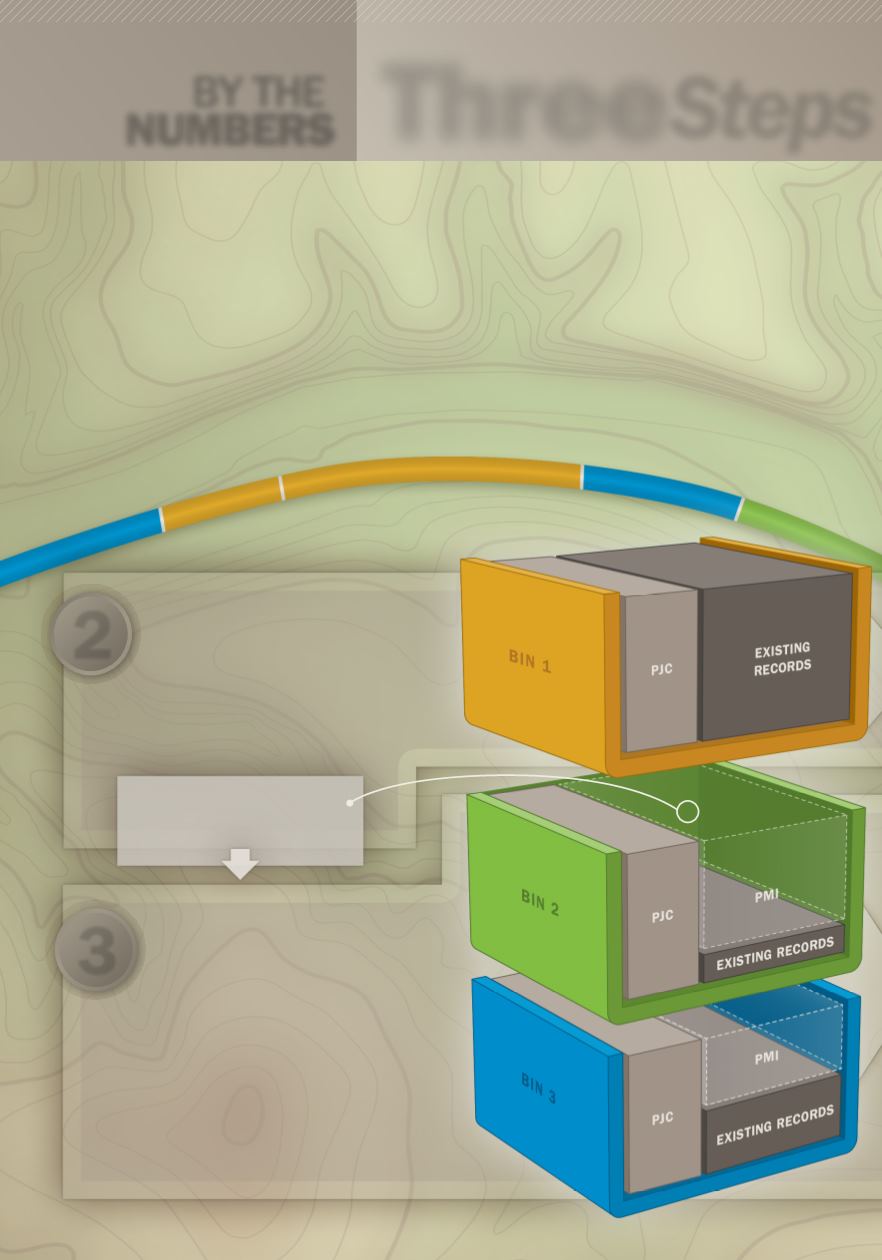

PIPELINES SHOULD HAVE TRACEABLE, VERIFIABLE, AND

COMPLETE RECORDS,

including material documentation to

support maximum allowable operating pressure (MAOP) validation.

But what about pipeline segments that are decades old? Or assets

that were once managed by one operator, sold to another, and then,

potentially, sold again?

The answer? Pipe Identification (PI).

Correlate existing pipe records,

if any, to the PJC bins.

If all records align to a characterized

pipe bin, Pipe Identification has

been achieved.

If records gaps persist,

proceed to step 3.

Employ Positive Material

Identification (PMI)

– an in-situ non-destructive evaluation

methodology – to identify material

properties where records do not exist for

a given pipe joint or PJC bin. With all pipe

joints aligned to the appropriate bin, and

remaining gaps closed through PMI,

Pipe

Identification has been achieved.

Step

2

3